Los refrigeradores de absorción desempeñan un papel clave en los sistemas térmicos industriales. Estos sistemas sirven a sectores que necesitan una refrigeración constante y a gran escala. A diferencia de las configuraciones de compresión estándar, las unidades de absorción funcionan en un ciclo alimentado por calor. Este enfoque trae beneficios claros en la reutilización de la energía y el respeto del medio ambiente.

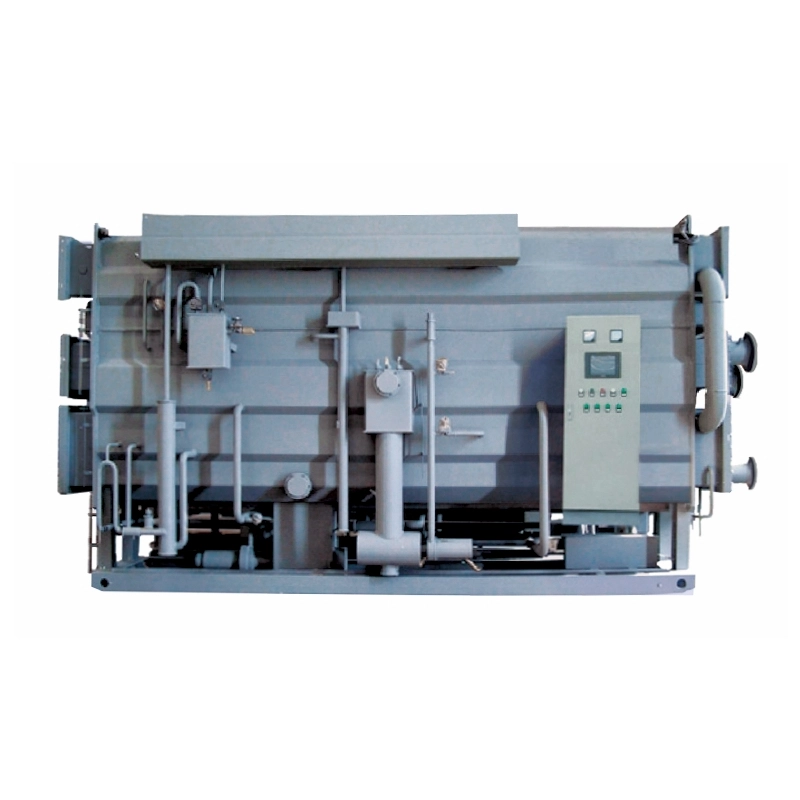

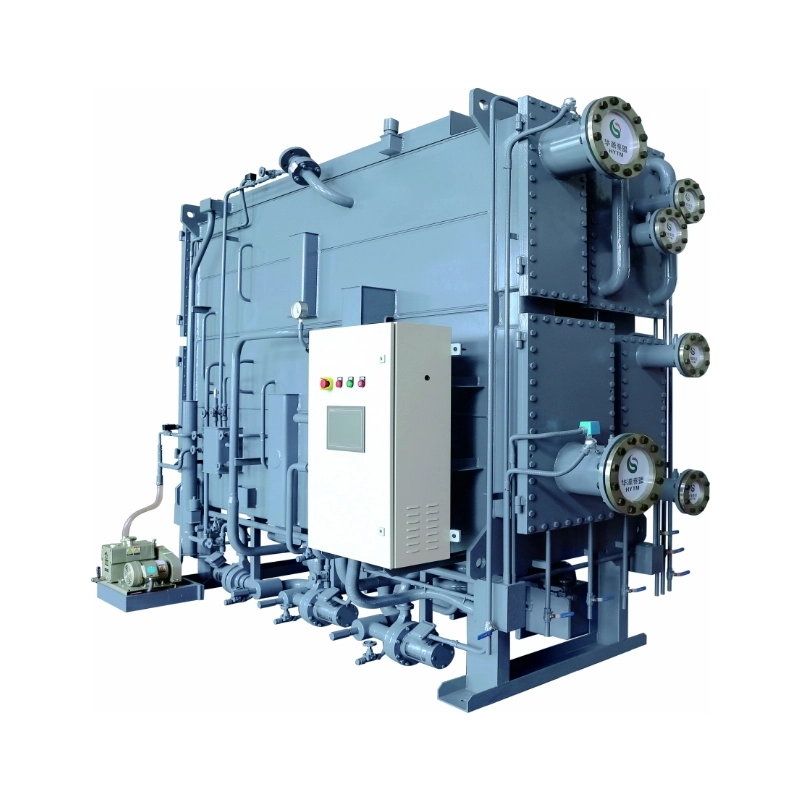

Si quieres soluciones inteligentes para configuraciones energéticas difíciles, MOON-TECH se centra en soluciones de integración de sistemas de refrigeración y calefacción, además de proyectos llave en mano. Con años de trabajo en proyectos en todo el mundo, MOON-TECH ofrece una gama completa de productos como compresores de tornillo, unidades de absorción y sistemas de recuperación de calor residual.

¿Qué hace que las unidades de absorción sean una opción preferida en el enfriamiento industrial?

Las unidades de absorción destacan por su habilidad en convertir calor de baja calidad en energía de refrigeración útil. Esto encaja bien con las industrias que generan mucho calor residual pero buscan reducir el uso de energía.

La operación impulsada por calor mejora la eficiencia energética

Energía de conducción: gas natural, vapor, agua caliente, etc. En lugar de depender de la electricidad como en los sistemas de compresión de vapor habituales, las unidades de absorción se basan en fuentes de calor como el gas natural, el vapor de fábrica o el agua calentada por el sol. Debido a esto, funcionan mejor en plantas que ya tienen calor de operaciones en curso.

Bajo impacto ambiental en comparación con los sistemas de compresión

Estas configuraciones utilizan refrigerantes verdes como agua o amoníaco. Ambas opciones muestran efectos muy bajos del calentamiento global y ningún daño al ozono. Estas características coinciden con la creciente necesidad de prácticas verdes en la industria.

Rendimiento fiable en aplicaciones de alta capacidad

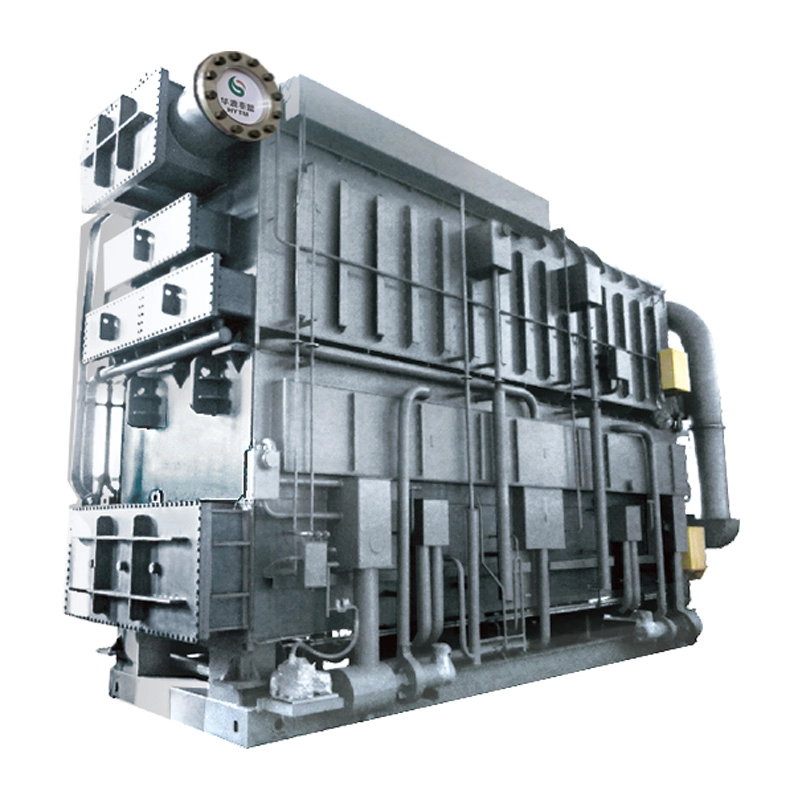

Aplicaciones del producto: Refrigeración industrial, refrigeración de aire acondicionado, refrigeración de distrito y calefacción. Los refrigeradores de absorción soportan cargas de refrigeración de 528,0 a 3517,0 kW. Se adaptan a grandes operaciones. En lugares como plantas químicas o fábricas metálicas, ofrecen resultados constantes incluso cuando las cargas cambian.

Generador: el punto de partida del ciclo de absorción

El generador marca el inicio del ciclo de refrigeración por absorción. Cambia la energía térmica en movimiento activo al alejar el refrigerante de la mezcla absorbente.

La entrada de energía térmica inicia el proceso de refrigeración

El calor añadido al generador a menudo proviene de gases de escape o quemadores de gas. Usted puede elegir una unidad de calefacción de gases de combustión que extrae calor de fuentes básicas como el suelo, las aguas subterráneas y las aguas residuales. Esto se hace sin aumentar otras necesidades energéticas. Por lo tanto, hace un buen uso de la energía residual sin necesidad de combustible adicional.

Separación de refrigerante y absorbente ocurre aquí

En el generador, el calor herve el refrigerante fuera de la solución absorbente a altas temperaturas. Este proceso de liberación libera el vapor refrigerante. Más tarde, ese vapor se condensará y evaporará para crear energía de enfriamiento.

Integración con unidades de fuego directo y de gases de flujo

Sistemas modernos como el unidad de calefacción a fuego directo dar una opción fuerte para los sitios que utilizan gas natural. Aquí, el gas natural se alimenta directamente a una unidad de combustión para la quema. Esta configuración logra un buen uso de energía y reduce las emisiones mientras mantiene la producción completa.

Condensador: transición de vapor a fase líquida

Después de la separación, el vapor se mueve al condensador. Allí, vuelve a la forma líquida. Este paso mantiene el bucle funcionando sin problemas.

El rechazo de calor facilita la condensación del refrigerante

El vapor del refrigerante libera calor al aire exterior o agua de refrigeración. En sistemas bien diseñados, este proceso reduce las barreras térmicas y aumenta el cambio del vapor al líquido.

Las condiciones de presión mantienen la estabilidad del sistema

Mantener la presión adecuada durante la condensación ayuda a mantener un flujo constante de refrigerante a lo largo de todo el ciclo. Como resultado, la transferencia de calor mejora y el equipo dura más tiempo.

Compatibilidad con el diseño modular del sistema

Las piezas del condensador en los refrigeradores de absorción más nuevos se adaptan fácilmente a construcciones modulares más grandes. Esto permite el crecimiento de las configuraciones y el mantenimiento sencillo en entornos de fábrica.

Absorbente: Recombinación de refrigerante y solución absorbente

Después de la condensación y evaporación, el refrigerante vuelve a unirse a la solución para terminar el ciclo. El absorbedor maneja esto a través de acciones químicas gestionadas.

La reacción exotérmica asegura un ciclo de absorción eficiente

El refrigerante líquido se remoja en la solución absorbente débil. Al hacerlo, emite calor. Esta acción de liberación de calor soporta el trabajo constante del sistema y las operaciones continuas.

La eliminación del calor mantiene la capacidad de absorción

Durante la absorción, el calor producido necesita ser eliminado para evitar la sobrecarga. Las buenas áreas de intercambio de calor y los controles de flujo son vitales para mantener el funcionamiento del absorbente en su punto máximo.

Mejor rendimiento a través de soluciones de ingeniería

Los nuevos diseños de absorbedores cuentan con guías interiores y configuraciones de pulverización que distribuyen los fluidos de manera uniforme. Estos pasos cortan las manchas no utilizadas y asegúrese de que la energía química se utilice plenamente. Tales diseños se adaptan a tareas industriales pesadas.

Evaporador: Entrega del efecto de enfriamiento al uso final

El evaporador sirve como la última parte del ciclo. Es el lugar donde ocurre el enfriamiento real. El líquido enfriado se forma aquí y se dirige a su uso objetivo.

La baja presión promueve la evaporación rápida del refrigerante

A baja presión, el refrigerante se convierte rápidamente en vapor. Absorbe calor del bucle de agua enfriada. Esta acción enfría los flujos de proceso o las rutas de aire en función de la configuración.

Enfriamiento directo de fluidos de proceso o corrientes de aire logrado aquí

En los entornos de fábrica, esta fase a menudo enfría elementos como reactores, tanques o líneas clave de inmediato. La parte’ La flexibilidad se adapta a diferentes tipos de carga.

Integración con unidades de recuperación de calor residual

Emparejado con un unidad de recuperación de calor residual de absorciónToma calor residual de baja calidad del trabajo de fábrica. Luego, lo convierte en una mejor energía para procesos de calefacción o sistemas de toda la ciudad. En general, esto aumenta el uso de energía y reduce los costos de funcionamiento.

¿Por qué elegir MOON-TECH para soluciones de enfriamiento por absorción industrial?

Necesita un socio que comprenda no solo piezas individuales sino redes térmicas completas. Aquí es donde brilla MOON-TECH.

Comprehensiva cartera de productos adaptada a las necesidades de la industria

El engranaje combina un ciclo de absorción completo utilizando tecnología de calefacción a temperatura de amplio rango y recuperación de calor residual. Equipo de refrigeración de absorción para herramientas de calefacción urbana, MOON-TECH cubre todos los aspectos del control térmico en las fábricas.

Experiencia comprobada en ingeniería y proyectos globales

Iniciada en 1956, MOON-TECH ayuda a clientes globales con soluciones de integración de sistemas de refrigeración y calefacción. Su amplio trabajo en diversos campos aporta conocimientos reales y configuraciones sólidas en condiciones difíciles.

Soporte de extremo a extremo desde el diseño hasta el servicio posventa

Desde la planificación de proyectos hasta la formación del personal, MOON-TECH aumenta la felicidad del cliente. Fomentan lazos duraderos y ayudan a obtener ventajas en el mercado. Su ciclo completo de servicio mantiene los sistemas funcionando bien y de acuerdo con los estándares con el tiempo.

Preguntas frecuentes

Q1: ¿Qué tipo de industrias se benefician más de las unidades de absorción?

R: Los sectores con mucho calor de bajo grado, como el procesamiento químico, la metalurgia y los centros de datos, ganan mucho. Reducen las necesidades de energía y mejoran la reutilización de la energía.

Q2: ¿Cómo se comparan los enfriadores de absorción ambientalmente con los sistemas basados en compresores?

R: Dependen de refrigerantes naturales como agua o amoníaco y usan mucho menos electricidad. Esto reduce la producción de carbono en un amplio margen.

Q3: ¿Puede una unidad de absorción trabajar con aplicaciones de calefacción y refrigeración?

R: Sí. Las unidades que manejan ambos modos pueden cambiar con las estaciones. Se adaptan a las necesidades térmicas durante todo el año.

Q4: ¿Cuáles son las fuentes de calor comunes utilizadas en las etapas del generador?

R: El calor proviene de gases de combustión, vapor, agua caliente o instalaciones de fuego directo con gas natural.

P5: ¿Cómo soporta MOON-TECH el mantenimiento después de la instalación?

R: Proporcionan ayuda completa del ciclo de vida como asesoramiento técnico, controles remotos, actualizaciones y capacitación del personal a través de su plataforma de servicio.