Au cours des dix dernières années, la réfrigération industrielle a beaucoup changé. Les prix élevés de l’énergie, les règles écologiques strictes et les besoins accrus de nombreux domaines ont poussé ce changement. Le nouvel équipement permet d'économiser de l'énergie, les commandes intelligentes surveillent tout et les unités faciles à cultiver s'adaptent rapidement. Tout cela garde également la planète à l'esprit et fait fonctionner les plantes sans pause.

Si vous avez besoin de suivre le rythme dans ce monde rapide, faites équipe avec un joueur de haut niveau. MOON-TECH conduit en technologie intelligente et ajustements personnalisés. Des systèmes de compresseurs à vis semi-hermétiques aux installations à ammoniac à deux étapes, ils sont conçus pour les travaux difficiles. Leurs unités travaillent dans le monde entier dans des camions à chaîne froide, des usines alimentaires, des lignes de fruits de mer et plus encore. Ils donnent une aide complète au projet et un soutien solide pour le fix-it.

Tendances dans la réfrigération industrielle moderne

La réfrigération industrielle se déplace rapidement pour répondre aux règles de puissance strictes et aux charges de travail quotidiennes. Les principaux changements apportent des compresseurs puissants, des unités de construction rapide et des outils de montre intelligents. Ces factures réduites, vous permettent d'ajouter plus tard, et garder le refroidissement stable.

Passer vers des systèmes de compresseurs économes en énergie

Les gens veulent des systèmes qui utilisent peu d'énergie mais qui sont beaucoup frais. Les nouvelles installations doivent réduire les coûts de fonctionnement et atteindre les marques mondiales de puissance.

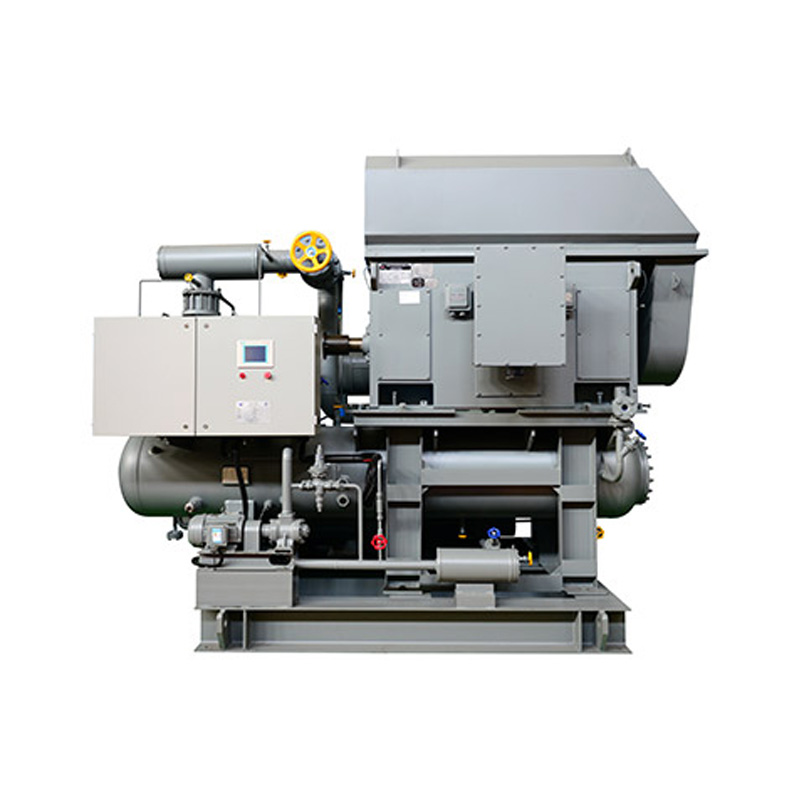

Une grande étape sont les compresseurs à vis semi-hermétiques. Le Unité de compresseur de réfrigération à vis semi-hermétique fonctionne bien de -40°C à 7°C. Il relie de nombreux compresseurs côte à côte. Cela vous permet de changer la puissance de refroidissement sur place et d'exécuter les commandes automatiques. Les coûts baissent et le refroidissement reste stable.

Les entraînements de changement de vitesse aident également. Les compresseurs ralentissent ou accélèrent le travail. La consommation d'énergie correspond exactement au besoin. Les heures hors pointe économisent beaucoup d'électricité. Les pièces durent plus longtemps parce que les démarrages et les arrêts sont doux.

Mettre l'accent sur les solutions modulaires et à glisser

Les plantes veulent une installation rapide et des réparations simples. Les paquets prêts à fabriquer et les unités de dérapage se vendent rapidement maintenant. Ils ont coupé le travail sur place.

Le Unité de compresseur à vis à deux étages séparée de type ouvert montre cela bien. Il brille dans les emplois froids. Les compresseurs haut et bas débutent l'un après l'autre. Alimentation d'huile par écart de pression. La puissance de refroidissement s'ajuste facilement. Vous glissez dans les plantes anciennes ou nouvelles avec peu de désordre.

Ces paquets grandissent avec votre travail. Petite ligne alimentaire ou immense entrepôt froid, ils s'adaptent et s'ajoutent plus tard.

Intégration de systèmes de contrôle et de surveillance intelligents

Le refroidissement d’aujourd’hui fait plus que pousser l’air froid. Il ajoute des contrôles cérébraux. Vous voyez et modifiez le système tout le temps.

Les écrans numériques donnent des numéros en direct, détectent les problèmes et envoient des rapports au cloud. L'unité à vis semi-hermétique a cela intégré. Vous regardez de loin et réparez avant de grands arrêts.

Dans les salles de viande ou de poisson où le froid doit rester, les boîtes intelligentes maintiennent les températures correctes même lorsque les charges sautent.

Quel rôle joue la durabilité environnementale dans la conception des systèmes?

La pensée verte est assise dans chaque partie des nouvelles constructions de refroidissement. Du choix du fluide aux pièces en fin de vie. Les lois mondiales strictes et les objectifs de l'entreprise conduisent à cela.

Adoption de réfrigérants à faible PPG et de pratiques écologiques

Les fluides à faible GWP sont maintenant normaux. MOON-TECH examine le travail et choisit le meilleur fluide et la meilleure mise en page. Ils construisent le bon plan de refroidissement. Alors que les gens se soucient plus de la terre, de la sécurité et de l’économie d’énergie, MOON-TECH a fabriqué des systèmes de CO2. Ils ont conduit à une utilisation importante de CO2 et ont poussé à un meilleur refroidissement des magasins à la maison et à l'étranger.

Les unités utilisent des fluides naturels tels que le CO2 (R744) et l'ammoniac (R717). Ceux-ci froid fort et blesser l'air peu si manipulé correctement. L'équipement doit correspondre à ces fluides pour respecter les règles et rester vert à long terme.

Focus sur les technologies de récupération de chaleur et de réduction des déchets

Vert signifie plus que liquide. Capture de la chaleur résiduelle des boucles chaudes de gaz ou d'eau du compresseur. Utilisez-le pour laver l'eau ou la chaleur ambiante. Les plantes économisent de cette façon.

Des joints serrés et des outils de montre arrêtent les fuites de fluide. Même les petites coupes s'ajoutent. Moins de gaz échappe, l'air reste plus propre et le système fonctionne mieux.

Conformité aux normes environnementales internationales

Le respect des règles suscite de nouvelles idées. MOON-TECH conserve les marques vertes ISO14001 dans toutes les étapes de fabrication. Chaque unité répond aux soucis mondiaux de la terre et reste dure pendant des années.

Comment les exigences de performance ont-elles changé dans les secteurs industriels ?

Les emplois de refroidissement se sont agrandis et ont changé plus rapidement. Les lignes de viande ou les camions froids ont besoin de froid constant sous des charges sauvages et des taches rugueuses.

Demande accrue d'unités d'exploitation continue de grande capacité

Les installations 24 heures sur 24 ont besoin de compresseurs robustes. Le Unité de compresseur de réfrigération à vis à étage unique de type ouvert convient à cela. Il déplace l'air de 285 à 14 000 m³/h. Vous choisissez la configuration souhaitée. Il gère le froid élevé, moyen ou faible sans gaspiller d'énergie ou d'espace.

Personnalisation basée sur les exigences spécifiques à l'application

Chaque champ a besoin de son propre toucher. Les chambres froides diffèrent du refroidissement du poisson ou de la boisson fraîche. MOON-TECH vérifie les détails du travail et choisit le fluide et le système. Ils font le meilleur ajustement. De la correspondance fluide au niveau automatique ou à la séparation d'huile, les constructions personnalisées augmentent le travail et réduisent le risque dans des endroits spéciaux.

Fiabilité accrue dans des conditions de fonctionnement difficiles

Les unités font face à l'air salé, aux secoussements et aux grandes variations de température. Le métal robuste, les agencements intelligents et les pièces scellées les maintiennent en marche. Des tests en usine dures prouvent qu'ils durent. Plus de temps de travail, moins d'arrêts de réparation.

Pourquoi la compression en deux étapes gagne-t-elle en popularité?

Les emplois à froid inférieurs à zéro deviennent communs dans le gel rapide ou le refroidissement rapide. La compression à deux étapes gagne pour économiser de l'énergie à basses températures.

Amélioration de l'efficacité à basses températures d'évaporation

Deux étapes divisent la poussée. Moins de stress thermique à chaque fois. Le Unité de compresseur de réfrigération à vis composé à deux étapes de type ouvert donne un COP élevé inférieur à -25°C. Parfait pour le froid profond. Températures de gaz chaud inférieures économisent de l'huile et réduisent l'usure. Les temps de fixation s'étendent.

Meilleure gestion du pétrole et équilibre du système

Le refroidissement entre les étapes retire mieux l'huile. Moins de pétrole se déplace vers le bas et obstrue les échanges de chaleur. Le retour intelligent de l'huile maintient le lubrifiant à droite sans aide de la main. Le système fonctionne sans arrêt.

Gamme d'application étendue à travers les zones de température

Une unité en deux étages couvre de nombreuses pièces. Congeler à -40°C pour maintenir à -5°C. Pas besoin de configurations supplémentaires. Économise l'espace au sol et ajoute du contrôle.

Quelles sont les principales tendances de la demande du marché mondial?

Le refroidissement devient un must-have pour les mouvements alimentaires mondiaux. Les acheteurs veulent des paquets complets qui montrent des chiffres clairs, restent solides et suivent les lois vertes.

Croissance de l’infrastructure de la chaîne froide dans les économies émergentes

Les nouvelles terres construisent rapidement des chaînes de froid pour économiser de la nourriture et réduire les pertes après la cueillette. Cold Chain Logistics est en tête de liste d'utilisation pour la nouvelle technologie de refroidissement. Grande chance en Asie du Sud-Est, en Afrique, en Amérique latine. L'argent du gouvernement aide à mettre dans le refroidissement vert frais.

Préférence croissante pour les solutions d'ingénierie clé en main

Les acheteurs aiment les magasins à guichet unique. Concevez, construisez, configurez et sauvegardez à partir d'une seule équipe. Moins de confusion entre vendeurs. Le projet reste sur la bonne voie.

Des attentes croissantes en matière de transparence technologique

Les gens veulent voir des statistiques en direct. Temps de fonctionnement, consommation d'électricité, liquide à gauche. Tout sur l'écran ou le téléphone loin. Une vision claire crée la confiance. Les petits ajustements arrêtent les grandes factures tôt.

FAQ (questions fréquentes)

Q1: Qu'est-ce qui rend les compresseurs à deux étages plus efficaces que les unités à un étage?

R: Les compresseurs à deux étapes coupent la poussée par étape. Le gaz chaud reste plus froid. La consommation d'électricité baisse dans le froid faible.

Q2: Les systèmes de réfrigération modulaires conviennent-ils à des opérations à grande échelle?

R : Oui. Les systèmes modulaires commencent petits et grandissent. Adaptez les magasins alimentaires à des granges froides géantes.

Q3: Comment les commandes intelligentes profitent-elles aux utilisateurs de réfrigération industrielle?

R : Les contrôles intelligents regardent en direct, envoient des alertes de correction, partagent des notes dans le cloud et exécutent automatiquement. Moins de temps d'arrêt, moins de factures d'électricité.