Di dunia industri modern yang sibuk, menjaga tingkat suhu yang tepat memainkan peran penting ketika Anda menangani barang-barang yang rusak, memproses makanan, mengelola bahan kimia, atau menjalankan operasi logistik. Anda sering berurusan dengan naiknya biaya energi, bahaya barang rusak karena perubahan suhu, dan persyaratan untuk mengikuti aturan lingkungan yang ketat. Pengaturan pendinginan penyimpanan dingin terbaru mengatasi masalah ini secara langsung dengan menawarkan efisiensi yang kuat, kinerja yang dapat diandalkan, dan nilai nyata selama bertahun-tahun.

Jika Anda membutuhkan mitra yang dapat diandalkan di bidang ini, lihat lebih dekat Teknologi Bulan, sebuah bisnis yang dimulai kembali pada tahun 1956 dengan pengetahuan yang luas dalam solusi pendinginan industri. Sebagai salah satu pemasok kompresor sekrup dan sistem lengkap terkemuka di Cina, MOON-TECH berfokus pada pendekatan hemat energi seperti pengaturan kaskad NH3 / CO2 dan penggunaan suhu rendah. Berkat jangkauan di seluruh dunia dan metode produksi mutakhir, mereka memberikan paket proyek lengkap yang menempatkan keberlanjutan dan hasil yang kuat terlebih dahulu.

Mengapa Banyak Fasilitas Industri Masih Berjuang dengan Tagihan Energi Tinggi dan Kerugian Produk?

Banyak pabrik terus menggunakan peralatan pendinginan lama yang menggunakan terlalu banyak listrik dan berjuang untuk menahan suhu yang stabil. Kompresor yang lemah, transfer panas yang tidak efektif, dan hilangnya kontrol cerdas mendorong biaya utilitas lebih tinggi dan menyebabkan limbah produk secara teratur. Masalah semacam itu tidak hanya memotong keuntungan tetapi juga mengganggu alur kerja yang lancar dan menarik perhatian yang tidak diinginkan dari regulator. Beralih ke sistem yang lebih baru dan canggih memperbaiki sakit kepala umum ini dengan menekankan efisiensi yang lebih baik, kontrol yang akurat, dan kekuatan yang tahan lama.

Peningkatan Efisiensi Energi dan Penghematan Biaya

Anda dapat mengurangi pengeluaran energi Anda dengan sangat jelas dengan sistem pendinginan penyimpanan dingin yang direncanakan dengan hati-hati. Hari ini’ peralatan membuat penggunaan terbaik dari daya melalui bagian cerdas dan kontrol cerdas, yang membawa penghematan yang jelas dalam jangka panjang.

Mengurangi Konsumsi Daya Operasional

Kompresor sekrup yang kuat bersama dengan pendingin yang cocok seperti CO2 mengurangi kebutuhan listrik sambil mengelola permintaan pendinginan yang berbeda tanpa masalah. Akibatnya, pengaturan ini mencapai koefisien kinerja yang lebih baik, sehingga Anda menghabiskan lebih sedikit daya untuk mencapai efek pendinginan yang sama.

Biaya pemeliharaan jangka panjang yang lebih rendah

Pembangunan semi-hermetik yang mencakup lebih sedikit bagian yang rentan memakai menurunkan persyaratan layanan dan memperpanjang umur peralatan secara keseluruhan secara signifikan. Selain itu, pemeriksaan otomatis dan bahan yang kuat membantu menghindari kerusakan kejutan dan menjaga kunjungan perbaikan langka.

Desain Sistem yang Dioptimalkan untuk ROI Maksimal

Beberapa elemen penting membantu mempersingkat waktu yang dibutuhkan untuk memulihkan investasi Anda. Misalnya, perubahan kapasitas dari 15% hingga 100%, koefisien kinerja yang sangat baik, pemeriksaan otomatis untuk pemeliharaan dini, dan pemasangan mudah dengan pendingin alami bergabung untuk menghasilkan pengembalian keuangan yang solid dengan cukup cepat.

Kualitas Produk yang Superior dan Mengurangi Kerusakan

Penanganan suhu yang stabil menjaga barang yang disimpan Anda aman dan sehat. Pendinginan canggih menyebar bahkan pendinginan di seluruh ruang gudang besar, yang membantu menjaga kualitas tinggi dan mengurangi limbah menjadi minimum.

Kontrol suhu yang tepat dan seragam

Evaporator yang dibanjiri dikombinasikan dengan sistem kontrol cerdas menahan suhu tepat di mana Anda membutuhkannya dan menghentikan bintik hangat terbentuk. Akibatnya, akurasi yang hati-hati ini melindungi barang-barang halus tidak peduli di mana mereka duduk di dalam fasilitas.

Kemampuan Pendinginan dan Pembekuan Cepat

Pertukaran panas yang kuat memungkinkan sistem menurunkan suhu dengan cepat, yang berfungsi sempurna ketika beban baru tiba. Selain itu, proses cepat ini langsung mengunci kesegaran dan mempersingkat waktu yang dihabiskan produk dalam kisaran suhu yang berisiko.

Umur simpan yang diperpanjang di seluruh zona penyimpanan

| aspek | Sistem Tradisional | Sistem Banjir Modern |

| Stabilitas suhu | Fluktuasi hingga ± 5 ° C | Dalam ± 1 ° C |

| Kecepatan Pendinginan | Penggunaan energi yang lebih lambat dan lebih tinggi | Lebih cepat dengan pertukaran panas yang dioptimalkan |

| Pengurangan Tingkat Kerusakan | Garis dasar | Hingga 30% lebih rendah |

Desain kontemporer yang dibanjiri menciptakan lingkungan yang stabil yang memperpanjang kesegaran produk untuk periode yang jauh lebih lama. Oleh karena itu, Anda menikmati limbah yang jauh lebih sedikit di samping pergerakan saham yang lebih baik dan keuntungan keseluruhan yang lebih baik.

Peningkatan Keandalan dan Umur Panjang Sistem

Berhenti tak terduga dalam pendinginan dapat terbukti sangat mahal di lingkungan industri yang sibuk. Pengaturan pendinginan yang kuat memberikan operasi yang stabil berkat konstruksi yang solid dan fitur yang bijaksana.

Teknologi Kompresor Semi-Hermetik yang kuat

Unit seperti Unit Kompresor Pendinginan Sekrup Semi-Hermetik menunjukkan tingkat getaran rendah, pilihan pemantauan langsung, dan kerja yang dapat diandalkan pada suhu rendah mencapai hingga -40 ° C. Selain itu, rekayasa yang bijaksana menjamin berjalan stabil bahkan selama penggunaan sehari-hari yang berat.

Komponen Pertukaran Panas Tahan Lama

Pilihan pendinginan udara menghemat air berharga dan berdiri dengan baik terhadap karat, memberi mereka umur kerja yang sangat panjang. Selain itu, tindakan kondensasi yang konsisten mempertahankan efisiensi sistem yang tinggi musim demi musim.

Minimal Downtime Melalui Fitur Desain Lanjutan

Tambahan yang berguna seperti pengembalian minyak ejektor, manajemen tingkat cairan otomatis, dan pemasangan skid yang sudah dirakit menjaga semuanya berjalan lancar dan aman. Bersama-sama, sentuhan pintar ini memberikan kinerja yang dapat dipercaya sambil menjaga berhenti yang tidak direncanakan sangat langka.

Kepatuhan Lingkungan dan Keberlanjutan yang Lebih Besar

Anda terus merasakan tuntutan yang meningkat untuk memenuhi hukum lingkungan yang keras dan mengurangi jejak karbon Anda secara keseluruhan. Solusi penyimpanan dingin saat ini mencakup elemen ramah bumi yang cocok dengan target hijau di seluruh dunia dengan sempurna.

Penggunaan Refrigerant Alami dan GWP Rendah

Banyak pengaturan memilih CO2 atau amonia karena pilihan ini membawa dampak pemanasan global yang sangat sedikit. Dengan demikian, Anda menghindari pendingin sintetis yang lebih tua yang menghadapi penghapusan bertahap dan mempersiapkan pabrik Anda untuk aturan masa depan tanpa khawatir.

Mengurangi konsumsi sumber daya

Tata letak hemat air, terutama dengan kondensator pendingin udara, mengurangi penggunaan utilitas total dengan cara yang bermakna. Selain itu, berjalan yang sangat efisien secara langsung menurunkan emisi berbahaya dan mendukung manajemen sumber daya yang hati-hati.

Kepatuhan dengan Standar Internasional

Langkah-langkah keselamatan terpadu ditambah sertifikasi yang diakui membuat memenuhi pedoman lingkungan yang ketat menjadi mudah. Akibatnya, Anda mendapatkan jaminan nyata bahwa operasi Anda tetap sepenuhnya sesuai sekarang dan ke masa depan.

Mengapa Memilih MOON-TECH Sebagai Mitra Pendinginan Penyimpanan Dingin Anda

Memilih pemasok yang tepat memastikan pengaturan Anda menangani hari ini’ persyaratan saat tetap siap untuk besok’ Pertumbuhan S. MOON-TECH jelas unggul melalui keterampilan yang telah terbukti selama bertahun-tahun dalam pendinginan industri.

Unit Kompresor Pendinginan Sekrup Semi-Hermetik Inovatif

Unit tersebut menawarkan pengaturan paralel yang dapat beradaptasi bersama dengan pengawasan yang terhubung ke awan. Dengan demikian, Anda mendapatkan pengaturan fleksibel yang tumbuh dengan mudah di samping perubahan kebutuhan bisnis Anda.

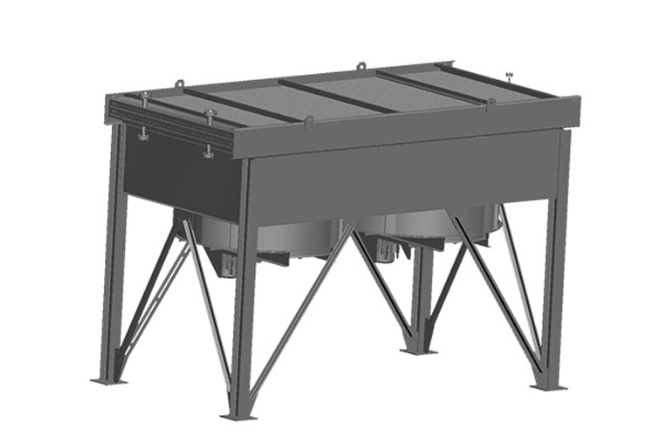

Chiller garam suhu rendah berkinerja tinggi yang dibanjiri

yang Chiller garam suhu rendah yang dibanjiri Performa luar biasa dalam pendinginan proses yang mencapai hingga -35 ° C dengan menggunakan cairan sekunder seperti etilen glikol. Ini memberikan peraturan yang tepat yang cocok untuk tugas industri yang menantang.

Penukar Panas yang Didinginkan Udara yang Efisien untuk Kondensasi yang Dapat Diandalkan

yang Penukar Panas yang Didinginkan Udara mengandalkan udara sekitarnya untuk menghemat air dan menyederhanakan pemeliharaan di daerah yang kekurangan pasokan air. Bagian yang berguna ini meningkatkan kinerja hijau total sistem.

Dengan menyeluruh dukungan layananAnda menerima kepercayaan penuh dari pengaturan awal melalui operasi harian dan peningkatan masa depan.

FAQ (Pertanyaan umum)

Q1: Berapa banyak biaya energi dapat dikurangi dengan sistem penyimpanan dingin modern?

A: Anda dapat mencapai pengurangan 20-40% melalui kompresor yang efisien, kontrol variabel, dan desain yang dioptimalkan.

Q2: Suhu apa yang cocok untuk pendinginan penyimpanan dingin industri?

A: Sistem dapat diandalkan menangani kisaran dari 7 ° C hingga -40 ° C atau lebih rendah, tergantung pada konfigurasi.

Q3: Apakah sistem ini ramah lingkungan?

J: Ya, banyak menggunakan pendingin alami seperti CO2 dan fitur komponen hemat air.

Q4: Bagaimana desain meminimalkan pemeliharaan?

A: Struktur semi-hermetik, lebih sedikit bagian bergerak, dan pemantauan otomatis menjaga pemeliharaan rendah.