In today’s industrial world, efficiency is more than a target—it’s essential. Energy costs keep climbing, and environmental rules get stricter. Businesses in areas like food processing, cold chain logistics, and seafood handling now rely on advanced industrial refrigeration solutions to stay ahead. These setups cut down on running expenses. They also deliver exact temperature control and steady performance in tough settings.

If you want a top player in this field, MOON-TECH delivers complete industrial refrigeration packages. They blend the latest tech with solid engineering. It supplies full refrigeration and heating system setups via one-stop turnkey projects to clients worldwide. With over 60 years in the business and work in more than 80 countries, MOON-TECH leads in creating energy-saving, eco-friendly cooling systems.

How Do Advanced Industrial Refrigeration Solutions Enhance Operational Efficiency?

A current industrial refrigeration setup goes beyond a basic cooling device. It combines tech, design, and automation to boost uptime and lower expenses. Key parts help improve operational efficiency in the ways below.

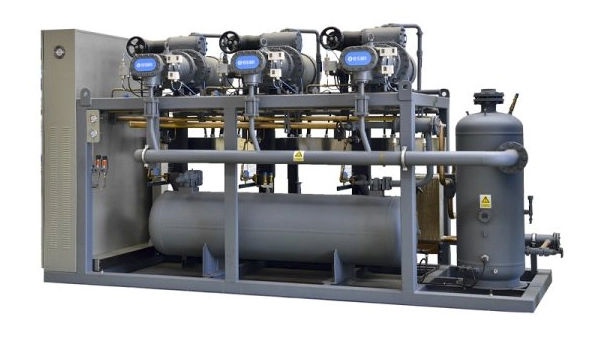

Integration of High-Efficiency Compressor Units

The compressor sits at the core of any industrial refrigeration system. New compressor builds cut energy use while keeping strong cooling output. Units like the Semi-Hermetic Screw Refrigeration Compressor Unit allow easy capacity changes and live tracking. Thus, they handle load shifts quickly. The built-in capacity control with strong automation and cloud data sharing suits tasks that need top efficiency.

Good oil separation and inside cooling features lengthen equipment lifespan. As a result, maintenance costs drop over time. These traits matter a lot in jobs with steady heat demands.

Automation and Intelligent Control Systems

Smart automation plays a key role in ongoing system tweaks. MOON-TECH adds PLC-based controls to its compressor units. These provide tight temperature handling and flexible load oversight. Live monitoring and cloud data sharing support quick choices. They also cut downtime via remote checks.

Such automation keeps the system in peak condition. It works well even when surroundings or output change. In turn, this boosts output and saves energy.

Modular Design for Flexible Installation

A modular system build gives great adaptability. Skid-mounted options, like the Open-type Skid-Mounted Separate Two-Stage Screw Compressor Unit, ease site setup and shorten install times. The step-by-step start cuts startup power spikes. Plus, modular setups make growth or changes simple based on capacity demands. They fit sites that expect expansion or fast rollout.

What Role Does Equipment Selection Play in System Efficiency?

Picking the proper compressor type for your use is vital for overall efficiency and steady running.

Matching Compressor Type to Application Requirements

For mid-temperature jobs with even heat loads, single-stage compressors provide a solid choice. The Open-Type Single-Stage Screw Refrigeration Compressor Unit ensures dependability with many refrigerants and cooling sizes. It covers displacement from 285 m³/h to 14,000 m³/h. So, it works for diverse industrial cooling tasks.

Two-Stage Compression for Low Temperature Applications

Low-temperature setups require tougher options. Two-stage compressors work best. They lower output temperatures and compression effort. The Open-Type Compound Two-Stage Screw Refrigeration Compressor Unit handles these well. Built for spots under -25°C, it gives much better efficiency than single-stage units with economizers.

Customization Based on Industry Needs

Refrigeration needs differ widely by sector. MOON-TECH picks the right fluid and system based on project details and real demands. It designs the best refrigeration setup for your case. This holds true whether you handle dairy or seafood storage. Tailored plans ensure solid heat control matched to your goals.

How Can Energy Consumption Be Minimized Without Sacrificing Performance?

You can lower energy use without losing output through smart built-in system features.

Use of Economizers and Intercoolers in System Design

Economizers pull heat from middle steps to boost heat efficiency. Intercoolers drop output temperatures. These parts lengthen compressor life and cut energy loss. They prove key for nonstop or big-scale work.

Variable Frequency Drive (VFD) Integration

VFDs adjust motor speeds to match current loads. MOON-TECH builds VFDs into compressor setups. This allows real-time energy tweaks. It cuts power use a lot during low-load times.

Heat Recovery Options for Sustainable Operations

Today’s systems do more than cool. They capture useful heat too. Total Heat Recovery Technology recovers condensation heat for 60–85°C hot water or 200°C steam. It fits the site’s needs. You can reuse this heat for defrost or water heating. Thus, it turns lost energy into real benefits.

What Maintenance Strategies Support Long-Term Efficiency Gains?

A properly cared-for refrigeration system keeps steady output and avoids downtime losses.

Predictive Maintenance Through Monitoring Systems

Modern sensors spot wear early, before breakdowns. MOON-TECH’s service tools give data-based upkeep tips. This forward-looking method stops surprise stops. It also prolongs gear life.

Simplified Access to Components for Routine Service

Modular parts allow fast reach to vital spots. This eases regular inspections and swaps without big halts. Standard parts across lines also simplify stock for spares.

Global Technical Support and Spare Parts Availability

MOON-TECH offers support in many languages via its worldwide network. Fast shipment of real spares keeps downtime short during fixes. This protects your production flow.

Why Should You Choose MOON‑TECH as Your Industrial Refrigeration Partner?

When picking a refrigeration teammate, track record, fresh ideas, and top service count.

Proven Engineering Expertise Across Industries

With over 60 years under its belt, MOON-TECH has supplied industrial refrigeration across more than 80 countries. Its skills cover food freezing, cold storage logistics, ice sports venues, and beyond.

Comprehensive Solution Portfolio Tailored to Client Needs

The firm provides a wide array of compressor units for uses like food processing, logistics, and chemical making.

Commitment to Innovation and Sustainability

As environmental care and safety grow, MOON-TECH has built CO2 refrigeration systems. It has pushed large CO2 use. This focus aids green running without cutting output.

End-to-End Project Support from Design to After-Sales Service

From first talks to post-sale help, MOON‑TECH gives turnkey packages. These include design advice, install guidance, startup, training, and upkeep.

FAQ

Q1: What industries benefit most from advanced industrial refrigeration solutions?

A: Industries such as food processing, cold storage logistics, seafood handling, and chemical manufacturing benefit significantly due to their demand for precise thermal control and operational efficiency.

Q2: How does a two-stage compressor improve low-temperature application efficiency?

A: It reduces compression ratios per stage, resulting in lower discharge temperatures and improved energy efficiency compared to single-stage systems.

Q3: Can MOON-TECH systems be customized based on operational needs?

A: Yes. MOON-TECH tailors its systems based on project-specific requirements including refrigerant type, cooling capacity, and industry application.

Q4: What maintenance features help reduce downtime in MOON-TECH systems?

A: Predictive diagnostics using sensor-based monitoring along with modular designs ensure quick servicing and reduced unscheduled outages.

Q5: Why is variable frequency drive (VFD) integration important?

A: VFDs allow compressors to operate at variable speeds based on actual load demand, optimizing energy use while maintaining performance stability.