In today’s busy industrial world, refrigeration systems keep food fresh and chemical processes steady. With energy prices climbing and tougher eco-rules in place, cutting power use and reducing emissions is a big deal. Smart refrigeration tech helps businesses save cash while being kind to the planet. As someone who’s dug deep into these systems for years, you can trust that companies like MOON-TECH stand out with their clever solutions. Started in 1956, this company has grown huge, serving over 120 countries with everything from super-cold cooling to reusing leftover heat. Their solutions handle tough tasks in food processing, petrochemicals, and city heating, backed by 263 patents and big awards like the National Science and Technology Progress Award.

Why Is Energy Efficiency Critical in Industrial Refrigeration?

A refrigeration system that eats up electricity hurts your wallet and the environment. But picking the right setup can change that fast. Imagine your monthly power bill. Shaving off even a small chunk could mean more money for your business.

Reduced Operational Costs

Efficient compressors can lower energy costs by about 20 percent in big operations. Take the 227,000-ton cold storage at Guangzhou Port. Its ammonia and CO2 cascade systems manage huge loads while keeping bills down. Savings pile up fast, especially in busy places like seafood plants where every penny counts.

Environmental Compliance

Using refrigerants with low impact on global warming makes meeting worldwide rules easier. You avoid fines and keep operations running. Over 560 projects switched from old HCFC-22 to CO2 tech, staying ahead of United Nations standards. No need to stress about outdated systems slowing you down.

Long-Term Sustainability

Sturdy equipment lasts longer, so you replace less and waste less. In Shandong’s 104,000-ton seafood storage, strong cascade systems keep going for years. Downtime drops, and so does material use. You gain confidence knowing your setup supports big goals like carbon neutrality without needing constant fixes.

How Do Advanced Compressor Technologies Improve Efficiency?

When your refrigeration system struggles with varying loads or extreme temperatures, it wastes energy and risks breakdowns, but cutting-edge compressors handle those demands with ease. Imagine a setup that adjusts on the fly, keeping things cool without extra power draw— that’s the kind of reliability that keeps operations humming.

Optimized Compression Ratios

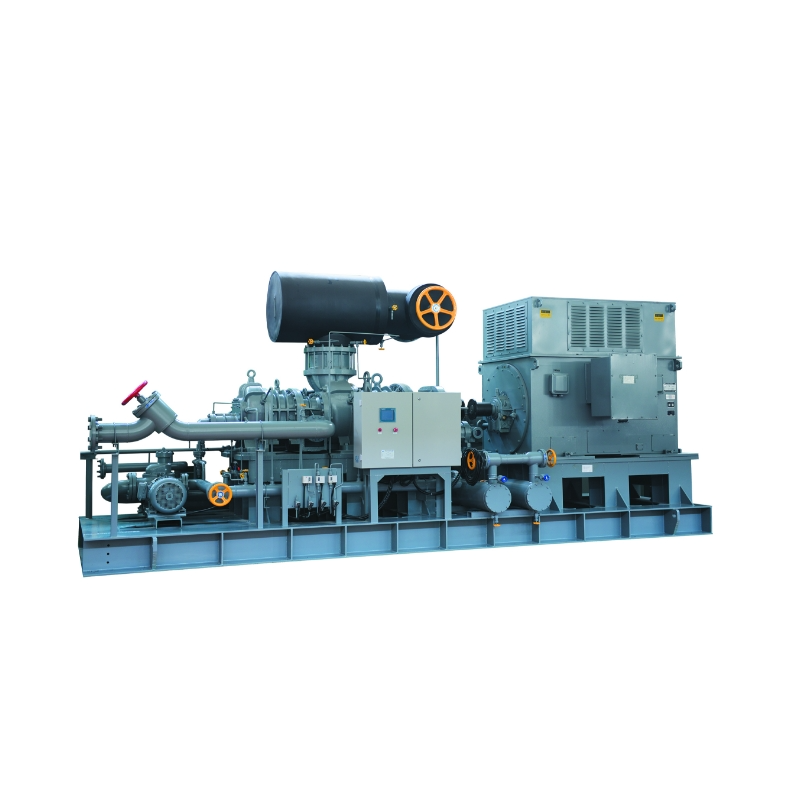

Two-stage designs excel at low temperatures down to -50°C, boosting overall performance in tough spots like natural gas liquefaction. The Open-type Skid-Mounted Separate Two-Stage Screw Compressor Unit shines here, delivering steady cooling for petrochemical plants. It handles high compression needs without spiking energy use, perfect for oilfield gas recovery.

Intelligent Control Systems

Real-time monitoring through PLC tech spots issues early, preventing waste. In automated cold storages like Thailand’s ASRS facility, NH3/CO2 systems with remote diagnostics maintain peak efficiency. You avoid surprises, like uneven temperatures that spoil goods or jack up bills.

Eco-Friendly Refrigerant Use

Natural options like ammonia and CO2 slash emissions compared to synthetics, aligning with green mandates. Over 2,200 CO2 units in various industries cut greenhouse gases significantly. Switching feels seamless, and the payoff shows in lower environmental impact without losing cooling power.

What Makes MOON-TECH’s Solutions Stand Out Globally?

Picking the right refrigeration partner can make or break your efficiency goals, especially if you’re dealing with international standards or diverse climates. You want systems that adapt, not ones that force you to rework everything.

Comprehensive Product Portfolio

From cryogenic units to heat recovery gear, options cover food freezing to data center cooling. The Semi-Hermetic Screw Refrigeration Compressor Unit fits mid-range needs with its compact build and support for multiple refrigerants. It’s ideal for spots like commercial estates or pharma labs where space is tight.

Global Project Experience

Installations span from Brunei’s 50-ton ice plant to Kazakhstan’s oilfield processing, proving versatility in harsh conditions. Partnerships with giants in refining and chemicals ensure tailored fits. You benefit from proven track records in places like Ecuador’s shrimp facilities, where daily 80-ton handling runs smoothly.

Innovative R&D Capabilities

Breakthroughs like -268.5°C helium compressors push boundaries, backed by 22 innovation platforms. Collaborations with academies yield LNG tech that’s now mainstream. These advancements mean your system stays future-proof, handling evolving demands without major upgrades.

Why Choose Modular and Skid-Mounted Designs?

Fixed installations often lead to lengthy downtimes and high setup costs, but modular options let you scale as needs change. Picture expanding your facility without tearing everything apart—that flexibility saves headaches.

Simplified Installation

Pre-assembled units drop into place fast, cutting weeks off project timelines. In Malaysia’s 24-meter fruit storage, quick deployment with ammonia systems handles varying temps from 0.5°C to 15°C. You start operations sooner, avoiding delays that eat into revenue.

Scalability and Flexibility

Adjust for growing demands by adding modules easily. Parallel operations in large plants like Shengli Oilfield manage flows from 500 to 50,000 Nm³/h. It fits small labs or massive warehouses, giving you room to grow without overcommitting upfront.

Reduced Maintenance Costs

Open designs allow easy part swaps, keeping fixes affordable. Materials resist corrosion in salty environments like offshore platforms. Regular checks through global networks minimize breakdowns, so you spend less on emergencies.

How Do MOON-TECH’s Solutions Align with Carbon Neutrality Goals?

Aiming for net-zero feels daunting with high-energy processes, but targeted refrigeration tweaks make it achievable. You can integrate recovery tech that pays off quickly, aligning with broader climate commitments.

Low-Carbon Refrigeration Systems

Cascade setups with NH3/CO2 avoid high-GWP refrigerants, reducing 800,260 tons of emissions yearly. Efficient units in 560 projects replace old tech seamlessly. Your facility contributes to goals like planting equivalent to 36 million trees without sacrificing performance.

CCUS Technology Integration

Capturing and storing CO2 from flue gases prevents releases, with 65 percent market dominance in core equipment. Liquefaction down to -55°C in Russian projects handles 40,000 tons yearly. You turn emissions into assets, like in enhanced oil recovery.

Energy Recovery Innovations

Distillation retrofits recover overhead heat, producing steam with 175 kWh per ton. Acetic acid towers save 4.15 million RMB annually while cutting 6,747 tons of carbon. These methods recycle 5.26 million tons of standard coal equivalents, lightening your environmental load.

What Are the Benefits of Choosing MOON-TECH for Your Business?

Deciding on a refrigeration provider boils down to trust—will they deliver on promises and stand by you long-term? You deserve a partner that anticipates needs, not one that reacts after problems arise.

Full Lifecycle Support

From planning to ongoing maintenance, 24/7 help covers installation, training, and upgrades. In Congo’s UN bases with 2,000-ton warehouses, complete steel and panel setups ensure reliability. You get end-to-end care, minimizing risks across the board.

Proven Industry Leadership

Dominance in niches like 80 percent of natural gas processing shows expertise. Ties with state-owned energy firms yield tailored solutions. You tap into experience from over 1,000 automated warehouses worldwide.

Commitment to Sustainability

ESG alignment through clean emissions and renewable integration keeps you compliant. Heat pumps and absorbers recover waste, saving 3.57 million tons of dust yearly. Your operations gain a green edge, appealing to eco-conscious clients.

FAQ

Q1: Are these solutions safe for food storage?

A: Yes, precise controls in units like screw compressors maintain temps from -35°C to 13°C, preserving quality in places like Ecuador’s shrimp plants.

Q2: What if your facility needs low-temperature cooling?

A: Two-stage compressors reach -50°C easily, ideal for gas liquefaction in oilfields like Kazakhstan’s projects.

Q3: How do they help with carbon goals?

A: By capturing CO2 and recovering heat, systems reduce emissions by millions of tons yearly, like in CCUS at Zhongyuan Oilfield.