In the search for green industrial cooling, CO2 (R744) has become the main natural refrigerant because it has zero ODP and very low GWP. Yet, picking between transcritical and subcritical setups is a key choice that affects your running costs and environmental impact directly. As you deal with these tough thermodynamic cycles, working with an experienced industry player is vital. MOON-TECH, set up in 1956, stands as a worldwide leader in refrigeration and heating setups. Known as a top 100 firm in the machinery sector and a leader in ozone protection, they offer full turnkey options and smart support. From low-temperature cooling to energy-saving heat reuse, their know-how makes sure your setup meets rules and works well for years ahead.

Overview of CO2 Refrigeration Technology and MOON-TECH Expertise

The move to natural refrigerants is not just a passing phase anymore; it is a basic need for current industrial setups. Grasping how CO2 acts under various pressure and temperature levels is the starting point for improving your plant’s energy use.

Growing Demand for Sustainable R744 Solutions

Worldwide rules on the environment push sectors to drop man-made refrigerants for R744. This natural choice gives strong heat transfer features and stays safe without toxicity or fire risk, which fits well for big cold chain work and food handling.

Fundamental Efficiency Differences in CO2 Cycles

The main difference comes from whether the refrigerant keeps under its critical point (subcritical) or runs over it (transcritical), and each cycle brings its own energy gains based on how heat leaves to the surroundings or another cooling line.

MOON-TECH Global Leadership in Carbon Neutrality

Through using modern BIM design ideas and smart control setups, the firm has put in the largest CO2 cascade systems globally. Their push for carbon neutrality comes from years of study and a strong worldwide service setup.

Mechanics of Transcritical CO2 Systems

Transcritical systems work in areas where outside temperature goes past CO2’s critical point (31.1°C), and in this mode, the refrigerant skips condensation to stay as high-pressure gas, which needs special parts to deal with the hard conditions.

Operation Above the Critical Point

In a transcritical cycle, the setup goes through gas cooling instead of standard condensation, which lets it run well even in warm summer times as long as it handles the high output pressures that follow.

Heat Rejection Performance in Modern Gas Coolers

How well these systems perform relies a lot on the gas cooler’s work, and by using good heat exchangers and smart fan controls, you can boost heat removal and keep a solid Coefficient of Performance (COP).

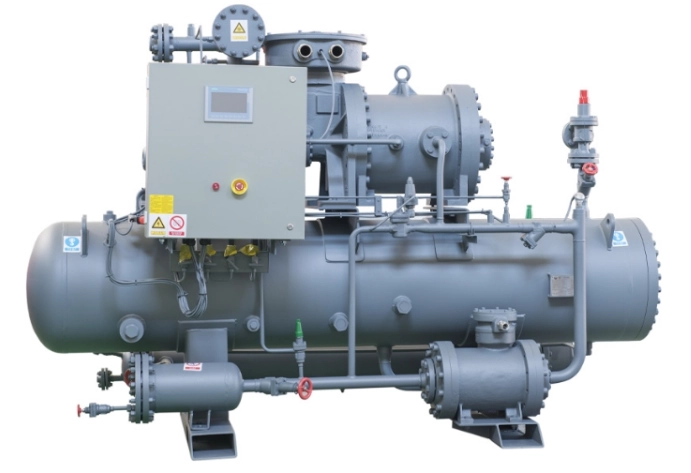

High-Pressure Management via Semi-Hermetic Screw Compressors

To keep steady work under these tough setups, the Semi-Hermetic Screw Refrigeration Compressor Unit serves as a core part. Its strong build and better sealing tech are made just for the high-pressure levels common in transcritical CO2 uses.

Efficiency Profiles of Subcritical CO2 Cycles

Subcritical systems often fit in cascade or backup cooling plans where CO2 stays under its critical temperature, and this way is known for its good energy use and lower running pressures when compared to transcritical types.

Stable Performance Below the Critical Point

By holding CO2 in a subcritical state, the system gains from the heat of vaporization, which moves thermal energy in an effective manner, and this steady state leads to even energy needs and less wear on machine parts.

Energy Advantages of Cascade System Designs

In a cascade setup, CO2 handles the low-temperature part while a different refrigerant takes the high-temperature side, which lets CO2 work in its best range no matter the outside weather.

Optimized Cooling with GEPT-R290 CO2 Units

For anyone wanting a very good subcritical choice, the GEPT-R290 CO2 High Efficiency Phase Change Refrigerating Unit brings a new option. This unit cuts problems like metal rust and high pump energy use that show up in old brine systems.

Direct Energy Efficiency Comparison Factors

To check the energy use of these two systems, you need to look past basic spec sheets, since you have to see how the system works with its surroundings and how much unused energy can go back into other tasks.

Impact of Ambient Temperature on System COP

Outside temperature stands as the top factor that changes CO2’s energy use, and while subcritical systems do best in cold areas or cascade plans, new transcritical systems with side-by-side compression can match them well even in hotter places.

Power Consumption Patterns in Industrial Applications

Your overall power cost comes from pump energy and compressor effort, and setups that use phase-change tech cut the power needed to shift refrigerants, which brings big yearly savings.

Heat Recovery Potential for Enhanced System Efficiency

A key plus of CO2 systems is the warm output gas temperature, and this heat can go to plant tasks or room heating, which turns your cooling setup into an effective heat pump overall.

Selection Guidelines for Industrial Refrigeration

Picking the best system means balancing location, task needs, and money aims, and a custom plan makes sure the tech you put in now stays good for many years.

Climate Suitability for Transcritical vs Subcritical

If your plant sits in a spot with steady high temperatures all year, a transcritical system with added efficiency fixes might suit best, but for cooler spots, a subcritical cascade system usually gives the best payback.

Total Cost of Ownership and ROI Analysis

Past the starting cost, you need to think about energy bills, upkeep, and how long the refrigerant lasts, and CO2 systems often have lower full ownership costs thanks to cheap refrigerant and strong build quality.

Custom System Integration by MOON-TECH Engineers

Expert advice is key for project wins, and skilled engineers can fine-tune hard pipe networks with BIM models to make safe builds and a good match for your exact process cooling tasks.

Core Advantages of MOON-TECH Solutions

Going with a partner that has deep making skills and a drive for new ideas gives the safety needed for big spending, and the power to check core part quality is what makes a top player stand out worldwide.

Advanced Manufacturing via Intelligent Digital Factories

The Hartford Compressor Digital Factory leads as the first in its field, using 3D printing and smart making to build single parts with great accuracy, which means every unit sent to your site hits top quality marks.

Reliable Performance of API 619 Standard Compressors

A lot of the main compressor units follow the API 619 standard in design, and this engineering level brings top sealing work and steadiness, which matters for safety and energy use in high-pressure CO2 spots.

Comprehensive One-Stop Turnkey Project Services

From first planning and design to site setup and tech training, you get a full service over the system’s life, and this all-in-one way cuts project chances of issues and keeps your refrigeration running at best from the start.

FAQ

Q1: Which CO2 system is more energy-efficient for extreme low-temperature cooling?

A: In most plant cases, a subcritical cascade system works better for deep-freeze tasks because it lets CO2 run at lower, steadier pressure with a higher COP.

Q2: Can transcritical CO2 systems work efficiently in tropical climates?

A: Yes, and with adds like parallel compression and ejectors, transcritical systems can reach good energy use even when outside temperatures often pass the critical point.

Q3: What are the safety benefits of using CO2 over ammonia?

A: CO2 lacks toxicity and fire risk, which makes safety steps simpler and cuts dangers from possible leaks in busy or key handling areas.