Learning how a screw refrigeration compressor unit works is key for better performance, lower energy use, and longer life in industrial cooling setups. If you run a cold storage site or a heat control plant, grasping the main parts and setups of these units helps you choose wisely. This affects costs and dependability.

For top solutions, check out MOON-TECH. It leads in worldwide cooling and heating system setups since 1956. Its full range of turnkey solutions covers design, setup, and ongoing care. MOON-TECH serves as a reliable partner in more than 120 countries. It focuses on green practices and new ideas. MOON-TECH brings fresh cooling tech for food handling, chemical cooling, and shipping fields.

Fundamental Principles of Screw Refrigeration Compressor Units

Screw refrigeration compressor units use turning compression methods to manage big amounts of refrigerant with good trust and savings. They work well in mid to large cooling systems. There, steady output under changing loads matters a lot.

Basic Working Mechanism of Screw Compressors

The main part of the screw compressor is a pair of rotors. One is male, and the other is female. They fit together to squeeze refrigerant gas. This happens as the gas moves along the rotors. The process cuts down space. It gives a steady flow, not sudden bursts. So, the system stays even and saves energy.

Oil spray helps seal, cool, and smooth the parts during squeezing. It keeps things running well, even with heavy loads or big pressure gaps. This setup cuts down on part wear. It also lengthens the unit’s life.

Thermodynamic Cycle in Cooling Systems

In a common cooling loop, the refrigerant takes in heat from the evaporator. Then, it gets squeezed to high pressure and heat. The compressor adds the main power. It pushes the loop along.

Next, the hot, high-pressure refrigerant gives off heat in the condenser. After that, it goes through an expansion valve. This drops its pressure and heat. Now, it can loop again. This shut cycle uses the screw compressor’s skill to hold pressure differences. It does this across different load needs.

Key Components and Their Functions

Every part in a screw refrigeration compressor unit adds to its work and lasting power. Careful building makes sure each piece fits tight for best trust.

Rotor Assembly and Compression Chamber

The male and female rotors lock in the compression chamber. They catch and squeeze refrigerant gas by shrinking space. Main parts come from advanced machines in Japan and Germany. This gives exact cuts. The thrust bearing uses special imported ones. They resist rust, stay young, handle heat, and keep high exactness. So, rotors stay straight over time.

Oil Separation and Injection System

Good oil handling is vital. The screw refrigeration compressor holds many national patents. These cover the rotor, oil separator, oil cooler, and oil pump. This shows tech strength. The oil separator pulls oil from the output gas for reuse. Meanwhile, the injection system controls oil spread in the chamber. It handles heat and seals.

Control Panel and Monitoring Systems

Built-in controls use programmable logic controllers (PLCs). They watch heat, pressure, and load in real time. Auto features boost safety. They also keep top work across speed ranges.

Types of Screw Refrigeration Compressor Units by MOON-TECH

Pick the right type based on size needs and heat levels. This is key for good savings. MOON-TECH has a few models for varied uses.

Semi-Hermetic Screw Refrigeration Compressor Unit

The Semi-Hermetic Screw Refrigeration Compressor Unit has a small shape with a built-in motor. This cuts space use. It fits cold storage jobs that need mid-to-low heat. It makes little noise. Maintenance is easy. So, it gives steady long-run work in tough spots.

Open-Type Single-Stage Screw Refrigeration Compressor Unit

This unit aims for bend and big cooling power. The Open-Type Single-Stage Screw Refrigeration Compressor Unit works for food lines and heat control in chemical sites. Its outside motor makes fixes simple. It also cools better. The unit takes many refrigerants like R717 and R507A.

Open-Type Compound Two-Stage Screw Refrigeration Compressor Unit

For very low heat jobs like quick freeze work, the Open-Type Compound Two-Stage Screw Refrigeration Compressor Unit gives better energy savings. It uses two-step squeezing. This setup cuts output heat and power waste. At the same time, it keeps work strong in deep freeze states.

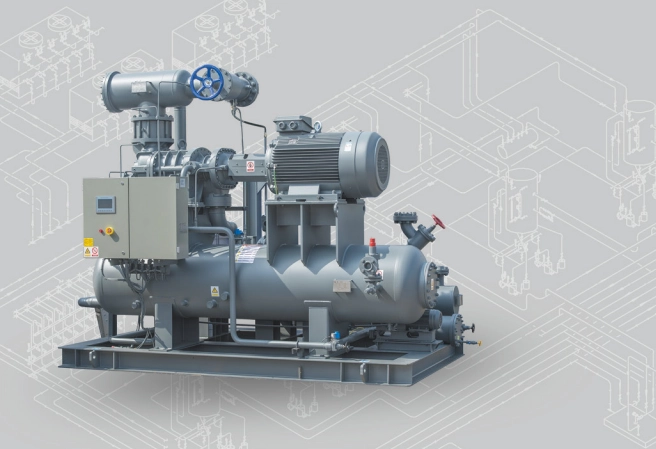

Open-Type Skid-Mounted Separate Two-Stage Screw Compressor Unit

The Open-Type Skid-Mounted Separate Two-Stage Screw Compressor Unit has a block design. It suits quick setup in big factory runs. It works for low-heat uses below -25°C. It saves more energy than one-step units with add-ons. This system lets custom plans. So, it fits smooth into large setups.

Support, Customization, and After-Sales Service from MOON-TECH

Putting in systems means more than picking goods. Tech help and fit services make sure full life value.

Engineering Consultation and Tailored System Design

Moon-Tech gives full plan help. It matches client wants smooth. Fixes come from load checks, refrigerant kinds, and area factors. They meet exact user needs.

Installation Guidance and Commissioning Services

Moon-Tech manages setup and join of systems with care and skill. This ensures sure work from the start. Help at launch cuts risks in first steps.

Maintenance Training Programs and Spare Parts Availability

Pro training for users builds skills in run and care of gear. A world ship net brings key spare parts on time.

FAQ

Q1: What is the core function of a screw refrigeration compressor unit?

A: Its core function is compressing refrigerant gas via twin rotors to facilitate heat exchange within the cooling cycle.

Q2: How does two-stage compression improve efficiency?

A: It reduces the compression ratio per stage, lowering discharge temperatures and minimizing energy losses under ultra-low temperature conditions.

Q3: What makes oil separation systems essential in these units?

A: They recover injected oil from discharge gas for reuse, ensuring thermal stability and lubrication while preventing system contamination.

Q4: Are MOON-TECH systems customizable for unique industrial requirements?

A: Yes, each system can be tailored based on refrigerant type, load demand, layout constraints, and environmental conditions.

Q5: How do you ensure long-term reliability in operation?

A: Through precision machining, advanced control systems, proper lubrication design, and comprehensive after-sales services including training and diagnostics.