Indonesia’s warm, humid weather, fast-growing farming, fish farming, and chicken industries, along with rising shipments of fresh fruits, vegetables, meat, and seafood, make a strong cold chain setup very important. Without good cooling, post-harvest losses can easily reach 30-40%, hurting both food supply and business profits. Sustainable storage tackles these problems by cutting down waste, lowering power use, and moving toward greener cooling agents that follow worldwide environmental rules. You can build lasting success with careful temperature management, smart system layouts, and field-tested equipment that copes well with everyday issues like moisture buildup and shaky electricity. A dependable choice in this area comes from MOON-TECH, a company started back in 1956 that brings long experience in low-temperature cooling and eco-conscious answers.

Indonesia’s Unique Challenges in Perishable Storage

Your fresh goods run into serious difficulties in Indonesia because of weather patterns and basic infrastructure limits. Getting familiar with these real-world hurdles lets you pick cooling setups that work steadily and last longer over time.

High Humidity and Tropical Climate Impact

The steady damp air speeds up spoilage and calls for accurate moisture removal together with cooling. Equipment needs to keep steady low temperatures without pulling too much electricity because of extra water in the air. This kind of careful balance helps protect product quality day after day in hot, sticky conditions.

Frequent Power Outages and Unstable Grid

Unpredictable electricity often leads to sudden temperature swings that damage stored items. Designs built to handle interruptions, along with efficient compressors, lower the risks tied to unreliable power supplies. Adding backup options becomes a practical step toward keeping everything running smoothly even during blackouts.

Strict Export Quality and Environmental Regulations

Buyers abroad demand steady high standards, and rules increasingly favor cooling agents with small environmental footprints. Switching to natural options lets you meet those requirements and steer clear of future restrictions or fines. Many operations in the region already show how well these changes work in practice.

Temperature Control for Different Perishable Types

Setting the right storage environment for each kind of product keeps freshness longer and maintains good appearance. Matching the cooling method closely to what the goods need avoids both too much cold and not enough.

Optimal Chilling for Fruits and Vegetables

Keep temperatures between 0°C and 13°C while holding humidity high to slow down breathing and rotting. Medium-temperature arrangements deliver gentle, even cooling that suits delicate produce very well. Careful control in this range helps deliver crisp, appealing items to markets or overseas buyers.

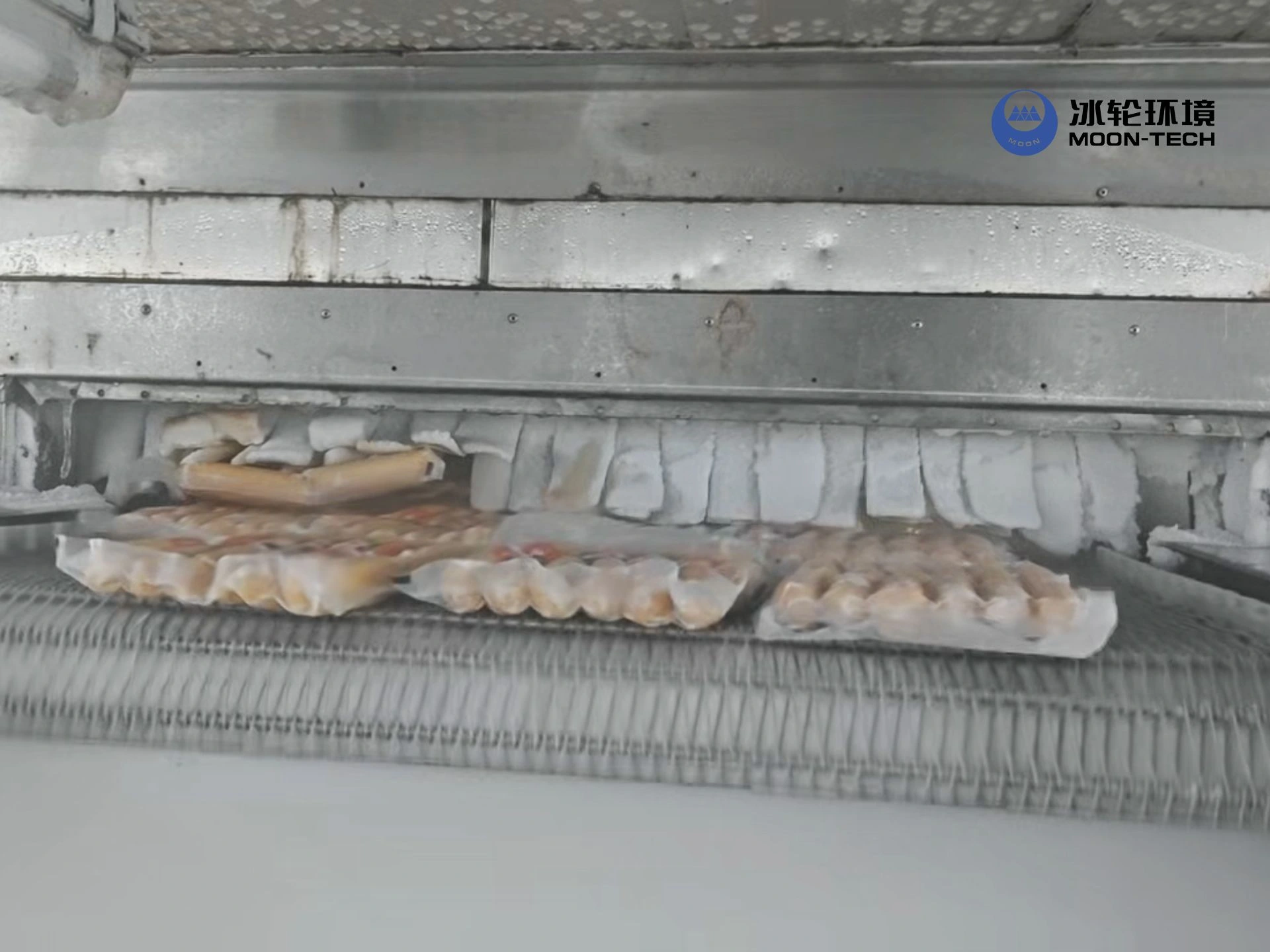

Freezing Techniques for Meat and Seafood

Quick freezing down to -18°C or even -35°C captures natural texture and taste. Individual quick freezing (IQF) through spiral freezers, already used successfully in big poultry setups across Indonesia, reduces large ice crystals and allows fast handling of large amounts. This approach keeps products separate and ready for packing or shipping without clumping.

Ultra-Low Temperature Preservation for High-Value Exports

Very deep freezing below -25°C works best for premium goods that need extra protection. Compound two-stage compression reaches those cold levels reliably while using less energy overall. Many exporters rely on this method to meet tough overseas quality checks.

Refrigerant Selection for Sustainability

Picking the proper cooling agent lowers harm to the planet and trims running costs at the same time. It also prepares your operation for stricter rules coming in the near future.

Advantages of Natural Refrigerants

Ammonia (R717) and CO₂ (R744) cause no damage to the ozone layer and show very low global warming numbers. When linked in cascade layouts, they combine strong points to reach better overall performance. Operators notice clear savings in power bills alongside cleaner environmental records.

Transitioning from HFCs to Ammonia and CO2

Moving away from high-GWP HFCs helps dodge future penalties and equipment bans. Reliable cascade designs that include secondary fluid loops add an extra safety layer, especially around food areas. Real installations in Southeast Asia prove the switch can happen smoothly without major disruptions.

Compliance with International Ozone and Carbon Standards

Natural agents fit well with major global agreements on climate and ozone protection. Practical examples from food processing plants in the region highlight how these choices support both rule-following and strong business results over many years.

Energy Efficiency and System Design Strategies

Well-planned layouts bring down electricity expenses and keep things dependable even under tough local conditions.

Cascade and Two-Stage Compression Benefits

Two-stage or compound arrangements hit very low temperatures while consuming noticeably less power. Open-type compound two-stage screw refrigeration compressor units perform especially well when heavy-duty freezing is required. Their steady output makes a real difference in high-volume settings.

Skid-Mounted and Modular Installation

Factory-built skid-mounted packages speed up setup and make future expansion easier. Open-type skid-mounted separate two-stage screw compressor units fit nicely in out-of-the-way locations where construction time matters. This approach cuts site work and lets you start operations sooner.

Smart Controls and Waste Heat Recovery

Automatic tracking systems fine-tune performance around the clock. Options that capture waste heat add further savings and improve total energy use. These features help keep costs predictable month after month.

Maintenance and Reliability Practices

Regular attention stretches equipment lifespan and avoids unexpected stops in difficult surroundings.

Leak-Proof and Low-Maintenance Designs

Semi-hermetic or carefully built open units greatly reduce the chance of leaks. Semi-hermetic screw refrigeration compressor units deliver sealed, dependable service with minimal routine attention. Operators appreciate the peace of mind that comes from fewer repair calls.

Automated Monitoring and Cloud Integration

Remote sensing spots small problems before they grow serious. Smart controls support forward-looking upkeep that prevents bigger breakdowns. This level of oversight keeps everything running without constant on-site checks.

Local Service Support and Spare Parts Availability

Worldwide networks provide fast help whenever needed. Full support through the entire product life cycle ensures quick fixes and steady performance. Having parts close by shortens any downtime significantly.

Why Choose MOON-TECH for Your Indonesian Cold Chain Project

Partnering with an experienced provider gives you access to field-proven knowledge in green refrigeration. Their history includes a major poultry processing effort spread across several provinces in Indonesia, where high-efficiency R717/R744 cascade systems drove more than a dozen spiral IQF freezers, each handling 2-3 tons per hour. That setup brought outstanding freezing results, clear energy reductions, lower carbon output, and solid dependability during heavy daily runs. Flexible choices like the open-type single-stage screw refrigeration compressor unit work well for medium-chilling tasks, while specialized models manage extreme cold without trouble. Complete turnkey services handle planning, installation, and continued care from start to finish. Reach out for personalized guidance on building sustainable storage that fits your exact requirements.

Conclusion

Building sustainable storage in Indonesia means facing weather-related difficulties with smart temperature handling, earth-friendly cooling agents, sturdy construction, and dependable upkeep routines. Putting these ideas into action safeguards your goods, shrinks losses, and opens doors for stronger export sales. Modern natural-refrigerant platforms together with reliable quick-freezing methods turn long-term goals into everyday reality.

FAQ

Q1: What makes natural refrigerants better for perishable storage in Indonesia?

A: They produce zero harm to the ozone layer and carry very low global warming numbers. In cascade setups they deliver strong efficiency and help meet worldwide environmental rules without extra penalties.

Q2: How can I handle power outages in my cold storage facility?

A: Select equipment featuring efficient compressors and flexible layouts that manage voltage changes well. Adding backup power connections provides extra protection so temperatures stay safe even during unexpected cuts.

Q3: What freezing method suits poultry and seafood best?

A: Spiral IQF freezing quickly freezes each piece on its own at very low temperatures. This preserves natural texture and quality while allowing large-scale processing without items sticking together.