Global rules are quickly getting rid of refrigerants that harm the planet. Energy prices keep going up, and many companies now have to pay carbon taxes. In this new reality, one natural refrigerant clearly wins the race: CO₂, also called R744. It has a global warming score of only 1, does not damage the ozone layer at all, and is neither poisonous nor able to catch fire. That makes CO₂ not just okay for today’s laws, it is completely safe from every future rule change for the next fifty years or more.

When businesses around the world search for a truly experienced partner who has already built hundreds of large CO₂ plants, they very often choose MOON-TECH. Started in 1956, MOON-TECH has grown into one of the biggest and most trusted makers of industrial CO₂ and NH₃/CO₂ cascade refrigeration systems on the planet. The company offers full turnkey service from the first drawing until the plant runs perfectly for decades.

Why the Industry Is Switching to CO₂ Refrigeration Systems?

The move is no longer just a fashion, it has become a must because of stricter laws, rising costs, and real pressure to become greener.

Zero Environmental Impact and Future-Proof Compliance

CO₂ has a warming effect of exactly 1 and is completely left out of every present and coming F-gas ban. When you choose CO₂ today, you will never again worry about new taxes or forced refrigerant changes.

Superior Safety for Food and Industrial Applications

CO₂ is not poisonous and cannot burn. If a leak ever happens, the gas simply spreads into the air without creating dangerous clouds or fire risk. That is why food factories and cold stores love it.

Dramatic Reduction in Carbon Footprint Over Lifetime

Even if the system sometimes uses a little more electricity in very hot weather, the total amount of carbon released during fifteen or twenty years of use is usually 30 to 60 percent lower than old HFC plants.

How CO₂ Refrigeration Systems Work?

Knowing the basic idea removes most worries about how well it really works.

Subcritical vs Transcritical CO₂ Cycles

When the outside air is cooler than about 31 °C, CO₂ works in a very efficient subcritical cycle, almost the same as normal refrigerants. When it gets hotter, the system quietly changes to transcritical mode and uses a gas cooler instead of a normal condenser.

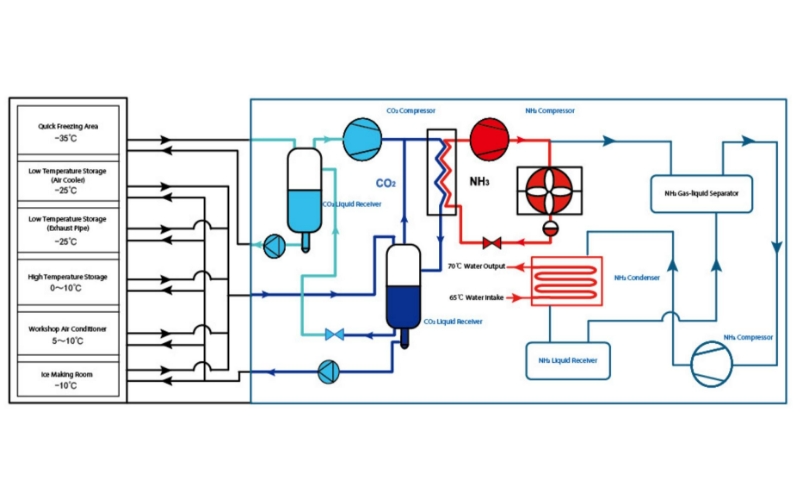

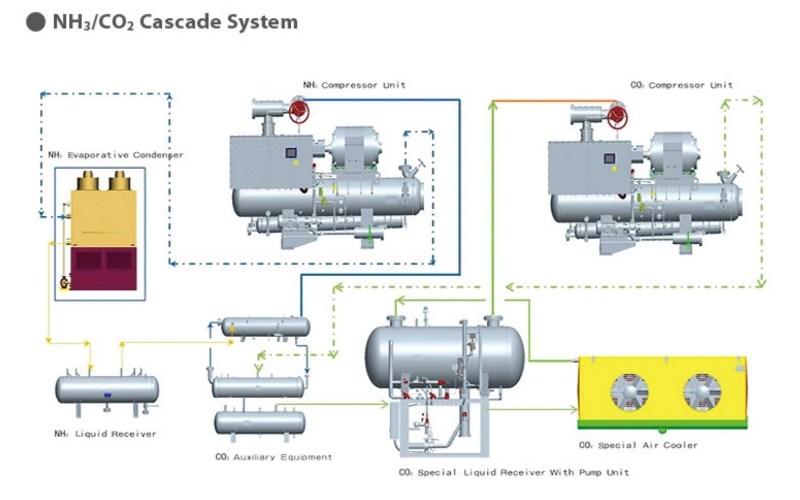

NH₃/CO₂ Cascade Systems: Best of Both Worlds

Ammonia stays safely inside the machine room where it gives fantastic efficiency on the warm side, while CO₂ flows through the cold rooms and production areas. You get top safety together with extremely low power use, even down to −50 °C.

Heat Recovery and Energy Efficiency Features

Today’s CO₂ plants can collect almost all the heat they produce and turn it into hot water or heating for buildings. Many factories now get free 60–90 °C water all winter long.

Key Advantages of CO₂ Refrigeration Over Traditional Systems

Real numbers make the choice easy.

Energy Efficiency Comparison

| System Type | Typical COP when making −10 °C cold | Yearly power use (compared to HFC) |

| Old HFC-404A | 1.8 – 2.2 | 100 % |

| Pure Transcritical CO₂ | 2.4 – 3.2 | 70 – 85 % |

| NH₃/CO₂ Cascade | 3.0 – 4.2 | 55 – 70 % |

Total Cost of Ownership Breakdown

| Cost item | HFC System | Transcritical CO₂ | NH₃/CO₂ Cascade |

| First purchase price | 100 % | 110 – 120 % | 115 – 130 % |

| Electricity bill | 100 % | 65 – 80 % | 55 – 70 % |

| Refrigerant cost & taxes | 100 % | almost 0 % | almost 0 % |

| Service and repair | 100 % | about 90 % | about 85 % |

| Total money spent in 15 years | 100 % | 70 – 80 % | 60 – 70 % |

Performance in High Ambient Temperatures

New designs with parallel compression, ejectors and water-spray gas coolers now give the same or better cooling efficiency as HFC even when the outside temperature reaches 40–45 °C.

MOON-TECH CO₂ Refrigeration Solutions You Can Trust

You do not need to be the first to try something new, the technology is already fully developed and tested for many years.

Full Range of CO₂ Compressor Units

From small 50 kW machines to huge single compressors over 2 MW, every unit is built only for CO₂ service in subcritical, transcritical or cascade use.

Proven NH₃/CO₂ Cascade Systems for Large-Scale Cold Storage

These systems power many of the biggest low-temperature warehouses in the world because they use the least electricity and keep people completely safe.

Transcritical CO₂ Systems with Parallel Compression and Ejector Technology

Ready-made packages include heat recovery, smart controls and remote monitoring so you reach the toughest energy and carbon targets without extra work.

Common Concerns and How They Are Solved?

Most remaining questions disappear once you know the true story.

High Pressure Myth: Safety Design Standards

All pipes and vessels follow the strictest international pressure rules with several backup safety valves and automatic emergency shutdown. Daily operation is as safe as ammonia when correct standards are used.

Performance in Hot Climates: Advanced Technologies Used

Modern ejectors, extra compressors running in parallel and mist cooling on the gas cooler have removed the old hot-weather problem. Plants in very warm regions now run with the same or lower power cost than HFC.

Initial Investment: Fast ROI and Available Incentives

The higher price you pay at the beginning normally comes back in three to six years because of lower electricity bills, no refrigerant tax and many government green-energy grants.

Is CO₂ Refrigeration Right for Your Project?

Ask yourself a few simple questions:

- Do you need temperatures below −5 °C or large frozen storage space?

- Is food safety or worker safety very important to you?

- Are you building a new factory or planning a big upgrade soon?

- Do you want to stop worrying about future refrigerant bans forever?

If you said yes to any of these, CO₂ is very likely the smartest choice for you.

FAQ

Q1: Is CO₂ refrigeration really more expensive to buy?

A: The machines cost 10–30 percent more at the start, but you save 20–40 percent of the total money over fifteen years because electricity and refrigerant taxes become much lower.

Q2: Can CO₂ systems work well in very hot countries?

A: Absolutely. New technology such as parallel compression and ejectors make today’s CO₂ plants run just as well, or better, than old HFC systems even when it is 40–45 °C outside.

Q3: Is the high pressure dangerous?

A: Not at all. CO₂ systems use the same safety rules and backup devices as ammonia plants. When built correctly, they are among the safest options available.