Factory cooling and heating setups differ a lot in how they are built, how much power they use, and what jobs they fit best. Among popular options, absorption units and screw compressor systems show two very different ways to handle heat. Knowing how they work, their results, and effects on nature can help pick the best choice for your factory job.

If you face tough choices in picking systems, MOON-TECH gives full ready-to-use plans that mix screw compressor and absorption tech made just for your factory needs. With decades of work, MOON-TECH stands as professional maker of screw compressors. They blend exact building with new heat tech. From system joining to world-wide help and project advice, their group brings trust and top work in food making, moving goods, chemicals, and area energy areas.

Overview of Absorption Units and Screw Compressor Systems

Absorption and screw compressor systems vary a lot in how they make cooling or heating. Absorption units run on heat sources. Screw compressors work with machine power. This leads to clear differences in how well they save power and what jobs they suit.

Fundamental Principles of Operation

Absorption units use heat power and chemical taking-in steps to move heat. They often pick pairs like water/lithium bromide or ammonia/water. These help changes in form without machine squeezing.

Screw compressors use two twist rotors to squeeze coolants. This machine way needs a lot of electric power. But it reacts fast to changing cooling needs.

The main difference is in the power input. Absorption units use extra heat or steam. Screw compressors use power straight from the motor.

Key Components in Each System

An absorption unit has four main parts: absorber, generator, condenser, and evaporator. They form a closed loop. In it, coolant and taker swap jobs.

A screw compressor system has a motor, compressor body, oil separator, and control setup. The Semi-Hermetic Screw Refrigeration Compressor Unit joins easy power change with many compressors working together. It also has smart auto controls for live checks.

Energy Efficiency and Operational Costs

Power supply matters a lot when choosing these techs. Using ready heat or needing quick answer from electric systems changes cost plans and green goals.

Energy Source Requirements

The second-type absorption heat pump, known as a temp-raise heat pump, takes in much mid-temp heat to make a bit of high-temp useful heat. This helps factories with lots of extra heat cut down on electric use.

Screw compressor systems need steady electric flow to keep pressure. They work well in changing spots. But this raises running power costs.

The Type-II Absorption Heat Pump Unit is built to catch low-level heat. Its COP often stays between 0.4 and 0.5. This fits well for heat reuse jobs where power is short.

Lifecycle Cost Considerations

In places with plenty of heat, absorption systems cut running costs. Yet they answer load changes slowly. They also need steady heat input.

Screw compressors react fast to load shifts. But they can build up bigger power bills over time. Their strong build lasts long with good care. This gives good full-life costs in heavy work spots.

Application Scenarios and Suitability

Pairing the best system with your factory’s heat setup is key to max power saving and meeting work needs.

Industrial and Commercial Use Cases

Absorption units fit well in spots with extra heat, like chemical factories or steel plants. They use waste hot water or steam exhaust. This makes them great for factory heat jobs or heat steps.

Screw compressor systems suit better in places that need quick cooling rounds, such as cold storage or steady make lines. Their parts fit together for exact control in changing loads.

With custom build plans, MOON-TECH gives made-to-fit cooling and heating fixes that match your work setup.

Environmental Conditions and Load Profiles

Absorption systems do good in steady load spots with even heat supply. If your work runs on fixed heat making, like joint power plants, absorption is a smart pick.

Screw compressors shine in changing loads thanks to their adjust powers. Live speed changes let them answer well without extra work.

Performance Metrics and System Control Strategies

System results change with air around, liquid traits, and power source facts. Knowing these numbers helps place them right.

COP (Coefficient of Performance) Comparison

For absorption units, COP ties close to the temp gap between generator and absorber. The COP of second-type absorption heat pumps stays under 1. It often falls from 0.4 to 0.5. This comes from how they turn heat input.

Screw compressors show higher COP in fair squeeze rates and good air spots. Changes in pull/out push pressures help better power saving.

Both systems aim for top saving when they run in their best ranges.

Automation and Monitoring Capabilities

Screw compressor systems often have PLC-based control setups. These do live checks, trend watches, and cloud links. They are key for smart factory joins.

Absorption systems can join with building control systems for team heat best plans across spots.

Far-check choices from MOON-TECH boost clear views in work. They spot faults and send care alerts early.

Integration With Existing Infrastructure

Your spot’s now setup often picks if a fix-up or new put-in works best. Both systems give join ease when built right.

Retrofitting Possibilities in Existing Facilities

Absorption units can join spots with now boiler or waste heat sources. This cuts extra money spend.

Screw compressors can swap old machine chillers with small pipe changes. Thanks to standard links and part fits.

Work-checks by MOON-TECH’s build team spot best up-grade ways through spot looks.

Customization Options Based on Project Needs

Part-based builds let both types grow by your output wants. Control think custom also makes sure fit with watch auto platforms now there.

MOON-TECH’s EPC team work way makes smooth joins in new builds or fix-ups. It has full tech match from plan to run.

Choosing the Right System With MOON‑TECH Expertise

Picking between an absorption unit and a screw compressor needs a check of many things. Base it on job needs, power ready, and green aims.

Evaluation Criteria for System Selection

Think about power type on hand, heat vs electric. Also look at cooling/heating wants over seasons. Add in area rules on coolants or emission caps.

Use MOON‑TECH’s fix advice for made ROI checks. These line gear picks with your big plans.

Recommended Products From MOON‑TECH Portfolio

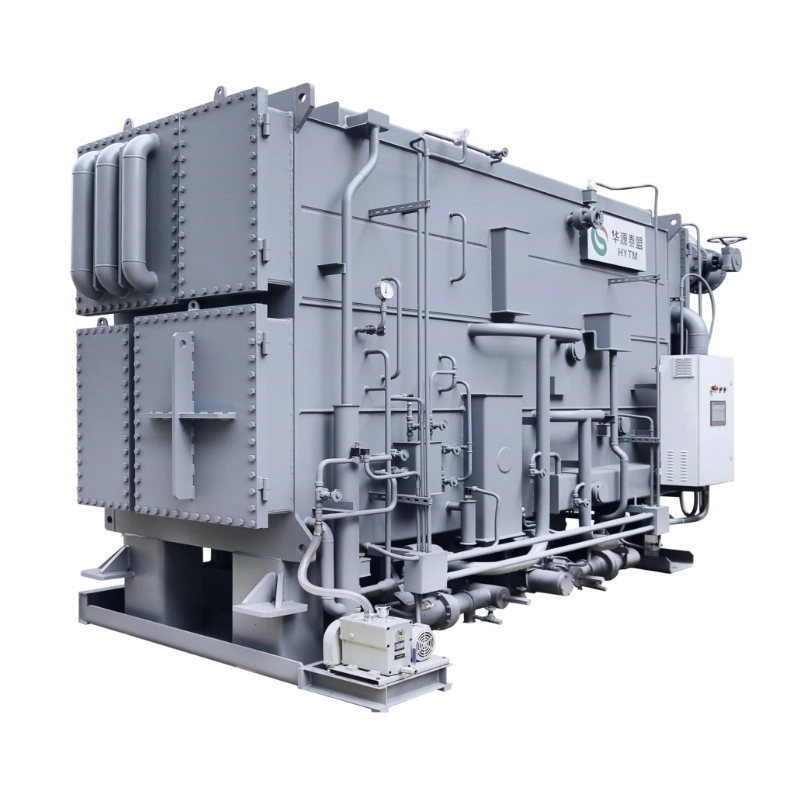

Type-II Absorption Heat Pump Unit

Takes much mid-temp heat source to make a bit of high-temp useful heat. Fits factories set on cutting carbon through heat reuse plans.

Semi-Hermetic Screw Refrigeration Compressor Unit

Gives easy power shift with built digital controls. Best for changing process cooling jobs in moving or food areas that need steady low temps.

Absorption Type Large Temperature Difference Heat Exchange Equipment

Cuts return water temp of main loop under 30°C. It keeps heating good in side loop. This proves key in main area heating nets with flow limits or low source temps.

FAQ

Q1: Can screw compressors handle rapidly changing load demands?

A: Yes, screw compressors have excellent modulation capabilities that adapt quickly to fluctuating thermal loads.

Q2: What is the typical COP range for Type-II absorption heat pumps?

A: The COP typically ranges from 0.4 to 0.5 due to the temperature-boosting nature of the system using low-grade heat sources.

Q3: Are there solutions for improving district heating efficiency?

A: Yes, absorption type large temperature difference heat exchange equipment enhances heating efficiency by lowering return water temperatures and increasing transmission capacity.

Q4: How do I know which system is best for my facility?

A: Evaluate your available energy sources, cooling/heating demand profiles, space constraints, and sustainability goals—then consult MOON-TECH experts for tailored recommendations.