In the food business, keeping products safe from farm to table is a constant challenge, especially with longer supply chains and stricter rules on freshness. Custom refrigeration steps in to solve those headaches, tailoring cooling to fit your exact needs whether you’re processing seafood or running a massive warehouse. As an expert who’s seen countless setups over the years, I can say companies like MOON-TECH really shine here with their practical fixes. They kicked off in 1956 and now cover over 120 countries, dishing out everything from deep freezing to smart logistics cooling. Their food solutions hit the mark for processing plants and cold chains, backed by 263 patents and national tech awards.

Why Is Temperature Control Vital for Food Safety?

Spot-on temperatures stop bacteria growth and keep nutrients locked in, but slip-ups can lead to recalls or lost trust from customers. You need systems that hold steady no matter the load, avoiding those costly mishaps in your daily grind.

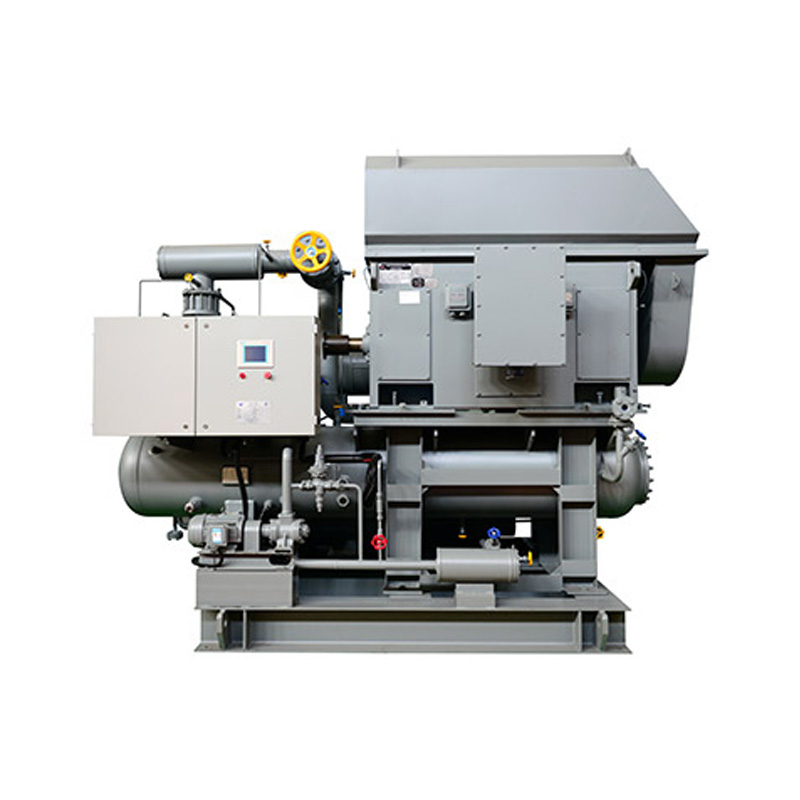

Precise Temperature Regulation

Holds steady temps for delicate items like seafood. The Open-Type Single-Stage Screw Refrigeration Compressor Unit nails this with reliable cooling. Like in Ecuador’s 650-ton shrimp setup where it keeps everything fresh during busy shifts.

Compliance with Food Standards

Meets tough rules from bodies like HACCP. Ammonia and CO2 mixes follow global guidelines without hassle. Keeps your operation clear of fines in spots like cold storages handling 300,000 tons yearly.

Reduced Food Waste

Cuts spoilage by even chilling. In Shandong’s 104,000-ton seafood hub, strong cascades drop losses big time. Saves cash and helps feed more people without extra effort.

How Do Custom Solutions Enhance Operational Efficiency?

Off-the-shelf coolers often waste power on mismatched loads, hiking your bills and slowing things down. Tailored ones fit like a glove, letting you ramp up output without extra fuss or downtime.

Tailored Cooling Capacities

Matches your exact daily needs in processing lines. The Open-Type Compound Two-Stage Screw Refrigeration Compressor Unit hits low temps for quick freezes. Thailand’s automated storage uses it to handle varying fruit batches smoothly.

Energy Cost Savings

Trims power draws in high-turnover spots. Guangzhou Port’s 227,000-ton facility sees big drops in bills from ammonia setups. You pocket more from those 20 percent cuts during peak seasons.

Streamlined Maintenance

Eases fixes with simple access points. Open designs let techs swap parts fast in salty seafood environments. Keeps lines running without long stops, like in Brunei’s 50-ton ice plant churning daily.

What Makes MOON-TECH’s Solutions Stand Out Globally?

Finding a refrigeration team that gets your food ops inside out beats guessing with generic gear every time. You deserve partners who blend tech smarts with real-world know-how for setups that last.

Advanced Compressor Technology

Delivers tough performance across food chains. Single and two-stage screws cover from chill to deep freeze. United Nations nods for green refrigerant swaps in over 560 spots.

Global Food Industry Expertise

Spans projects from Brunei’s ice factories to Kazakhstan oil-linked cooling. Wuhan hub’s 300,000-ton logistics runs flawlessly on tailored cascades. Ties with big refiners ensure food-grade fits.

Innovative R&D Capabilities

Pushes limits with 263 patents on low-temp tricks. Academy tie-ups birth mainstream LNG cooling for food. Keeps your plant ahead without big overhauls down the line.

How Do Eco-Friendly Refrigerants Benefit Food Operations?

Synthetic coolants jack up your carbon footprint and invite fines, but natural ones keep things clean and compliant. Switching pays off in ways you might not expect right away.

Lower Environmental Impact

Drops greenhouse gases from daily runs. Ammonia and CO2 cut 800,260 tons yearly across industries. Lines up with green pushes without skimping on chill power.

Regulatory Compliance

Handles phase-outs of old high-impact stuff like HCFC-22. Over 2,200 CO2 units prove it in food spots. Skirts penalties in markets cracking down hard.

Cost-Effective Operations

Saves long-term on refills and fixes. Brunei’s Freon and CO2 mix in ice plants trims ongoing costs. You see the difference in quieter bills over time.

Why Are Modular Designs Ideal for Food Facilities?

Rigid setups lock you into one size, but modular ones grow with your business without massive rebuilds. Think of it as building blocks for cooling that snap together easy.

Rapid Installation

Gets you up and running quick in tight spots. Malaysia’s 24-meter fruit warehouse deploys ammonia fast for 0.5 to 15°C ranges. Shaves weeks off startup headaches.

Scalability for Growth

Adds capacity as orders spike. Parallel runs handle 500 to 50,000 cubic meters hourly in big plants. Fits from small labs to sprawling food hubs.

Durable and Low Maintenance

Holds up in damp food environments with rust-proof parts. Open styles make swaps simple offshore. Global checks keep breakdowns rare and cheap.

How Do Custom Solutions Support Cold Chain Logistics?

Generic cooling breaks the chain with uneven temps, but custom ones seal gaps from truck to shelf. You keep products prime without extra worry on long hauls.

Seamless Supply Chain Integration

Links farm cooling to warehouse flows without hitches. Single-stage screws shine in logistics for steady holds. Wuhan’s multi-floor setup moves 300,000 tons yearly flawlessly.

Enhanced Product Quality

Locks in flavor and shelf life during moves. Ecuador’s shrimp lines preserve 80 tons daily with no dips. Builds your rep for top-notch goods.

Energy-Efficient Logistics

Trims waste in massive cold networks. Guangzhou’s ammonia cascades save big on 227,000-ton runs. Keeps costs down even in peak delivery crunches.

What Are the Long-Term Benefits of Choosing MOON-TECH?

Solo setups might work short-term, but a solid partner spots issues before they bite. You gain from teams that plan ahead for your food line’s twists.

Comprehensive Support Services

Covers from sketch to daily checks across borders. 24/7 aid handles installs and tweaks in 120 spots. Congo’s 2,000-ton bases run smooth with full panel fits.

Proven Industry Leadership

Holds 70 percent in carbon capture gear for food ties. Links with state energy players craft spot-on fixes. Tops 1,000 automated food warehouses worldwide.

Commitment to Sustainability

Blends clean vents and green mixes to stay compliant. Heat pumps cut 3.57 million tons of dust yearly. Gives your ops a fresh edge for green buyers.

FAQ

Q1: How do custom solutions cut food waste?

A: By holding steady temps, like in Shandong’s 104,000-ton storage dropping spoilage rates big time.

Q2: What refrigerants work best for food safety?

A: Ammonia and CO2, slashing emissions in over 560 projects while keeping goods fresh.

Q3: How does two-stage compression help in freezing?

A: Hits -50°C for quick freezes, perfect for seafood plants like Ecuador’s 80-ton daily runs.