In big factories that need cold storage or freezing, nothing hurts your wallet faster than a compressor motor that suddenly stops working. One hour of downtime can cost you tens of thousands of dollars. A burned motor can keep your whole plant shut for days or even weeks. Knowing exactly why motors break helps you stop it from happening. Even better, picking equipment that is built tough from the start keeps everything running smoothly for many years. That is why serious companies choose real experts like MOON-TECH, a trusted name in heavy-duty refrigeration since 1956. Their systems work reliably in more than 120 countries, from huge cold-storage warehouses to chemical plants.

What Are the Most Common Reasons Compressor Motors Overheat in Industrial Systems?

Overheating is still the biggest reason motors die. When the inside gets hotter than 140-160 °C, the wire coating melts fast and the motor is gone forever. Almost every overheating problem comes from three things you can actually prevent.

Electrical Imbalances and Voltage Fluctuations

Small changes in voltage or uneven power between phases make hot spots inside the motor. In plants that never stop, even a 10 % imbalance can push the temperature up by 30-50 °C. Good modern units have built-in monitors and gentle starters. These keep the current steady and safe from the very first second.

Inadequate Lubrication and Friction Buildup

Oil pulls heat away from bearings and moving parts. When oil gets old, runs low, or picks up dirt, friction goes way up. Today’s screw compressors come with smart oil systems. They control temperature exactly and keep oil clean no matter how hard the machine works.

Excessive System Load from High Ambient Temperatures

In hot places or rooms with bad airflow, motors always fight too much work. Bigger condensers and speed-changing drives remove heat quickly. This keeps the motor cool and happy even when the outside air is very hot.

How Does Poor Maintenance Contribute to Compressor Motor Breakdowns?

You probably already know maintenance is important. But missing small jobs speeds up motor damage much faster than most people think.

Neglected Filter Replacements Leading to Contaminant Ingress

Dirty filters let tiny hard pieces slip inside. Those pieces scratch bearings and rotors. Soon the motor runs hotter and pulls more power until it burns out. Changing filters on schedule is easy and cheap compared to buying a new motor.

Infrequent Oil Analysis and Level Checks

Oil can turn bad inside long before it looks dark. Bad oil eats the wire coating. Units that make oil checks simple with clear windows and easy sampling help you catch trouble early.

Delayed Vibration Monitoring and Alignment Adjustments

If parts get out of line after install or when the floor settles, tiny shakes turn into big damage. Motors placed on strong, shake-proof bases with built-in vibration watchers warn you long before anything breaks.

Why Do Contaminants Cause Premature Failure in Refrigeration Compressor Motors?

Water, acid, and dirt work quietly. By the time you notice, the harm is already done.

Moisture Accumulation from Leaky Seals

Water mixes with refrigerant and makes acid. Acid eats wire coating and rusts bearings. Fully sealed semi-hermetic screw refrigeration compressor units have no shaft seal at all. So water never gets inside.

Dust and Debris Infiltration via Poorly Sealed Intakes

In dusty factories, open motors suck dirt right onto the wires. Sealed designs with clean air breathers stay spotless for many years.

Refrigerant Contamination from System Leaks

Extra air that cannot condense raises pressure and heat. Smart automatic air removers and top-quality oil separators keep the refrigerant pure. This protects the motor for a very long time.

What Role Does Improper Sizing Play in Compressor Motor Failures?

Picking the wrong size is one of the quickest ways to ruin a motor.

Undersized Units Struggling with Peak Demands

A motor that is too small runs at full power all the time. It overheats in weeks instead of years. Doing the math correctly and adding a safe extra margin stops this problem completely.

Oversized Motors Leading to Short Cycling

A motor that is too big turns on and off too often. Every start stresses it and moves oil away from where it is needed. Modern screw compressors change their power to match the exact cooling need. So they never short-cycle.

Ignoring Application-Specific Capacity Needs

Very cold jobs need bigger motors than mild jobs for the same amount of cooling. Having both two-stage and single-stage choices lets you pick exactly what your plant needs.

How Can You Prevent Compressor Motor Failures in Harsh Industrial Environments?

Stopping trouble before it starts is always smarter and cheaper than fixing it later.

Implementing Robust Cooling and Ventilation Protocols

Open designs with lots of airflow and water-spray condensers keep motors cool even when the room reaches 45 °C or more.

Adopting Advanced Diagnostic Tools Early

Sensors that watch shaking, power use, and wire temperature send phone alerts the moment something looks wrong. Many new units already have these sensors built in.

Scheduling Proactive Component Inspections

Trained experts spot oil problems, bearing wear, and tiny misalignments long before they become big headaches. Good service plans make booking those checks very simple.

Why Choose Advanced Screw Compressor Units to Avoid Motor Failures?

Not every compressor protects its motor the same way. Some are clearly built tougher.

Superior Build Quality with ASME-Certified Components

Strong rotors, top bearings, and extra-large motors made to strict world standards last decades where normal units give up much sooner.

Energy-Efficient Designs Reducing Overload Risks

Smart sliding valves and super-efficient motors use 10-30 % less electricity. Less current means much less heat and stress every day.

Comprehensive Warranty and Global Support Network

Long warranties and parts available any time, anywhere, mean you never lose weeks waiting for a fix.

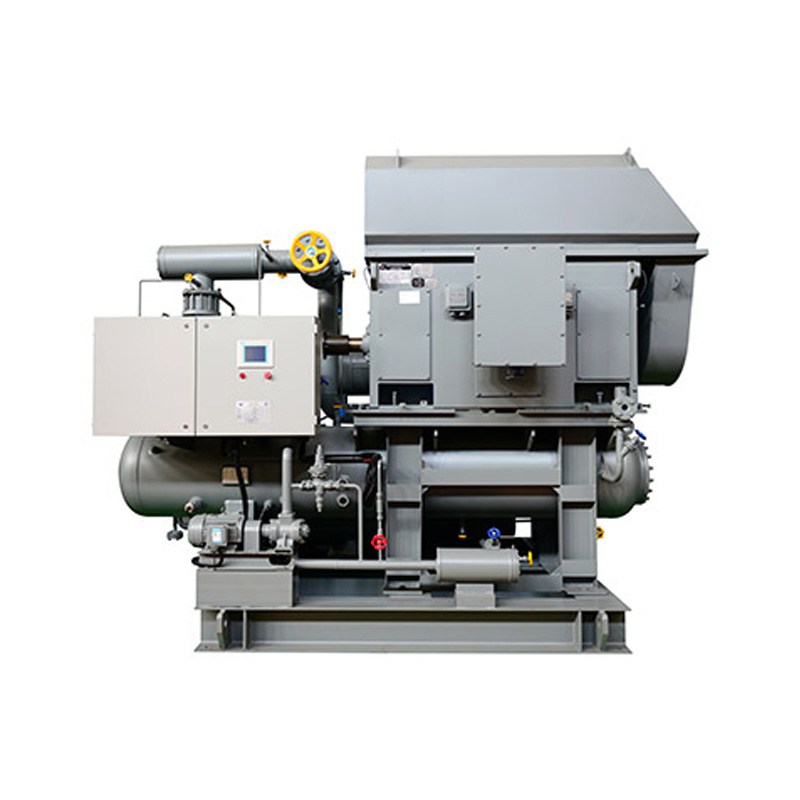

When you need really low temperatures down to -50 °C, the open-type skid-mounted separate two-stage screw compressor unit gives outstanding dependability. The motor sits completely separate, so service is quick even in the coldest, hardest jobs.

For regular cold rooms and factory cooling, the open-type single-stage screw refrigeration compressor unit delivers proven toughness and low running cost season after season.

FAQ

Q1: How long should a compressor motor last in industrial refrigeration?

A: When everything is sized right, looked after well, and built with modern protection, fifteen to twenty-five years is completely normal. Many new screw units go past 100,000 hours without ever needing a new motor.

Q2: Is overheating always easy to see before a motor fails?

A: No. The wires inside can get very hot even when the outside still feels okay. Sensors placed right inside the windings give the first and truest warning.

Q3: Do variable-capacity compressors really save enough power to be worth the price?

A: Yes, every time. They use twenty to forty percent less power at part load. Most plants get their money back in two to four years, then enjoy free savings for many more years.