In industrial cooling, one term stands out more than others—refrigeration. It acts as more than a simple job. It serves as the main driver in every chiller system. The aim might be to keep food lines steady. Or to hold manufacturing processes with heavy loads in check. It could also mean helping key infrastructure stay cool. Refrigeration lowers temperatures, sure. But it also gives you real control over operations.

If you want solid cooling setups for engineering needs, check out MOON-TECH. This company started back in 1956. Their gear works in tough spots. These include cold storage chains and chemical cooling tasks. MOON-TECH earns praise for its strong tech side. The firm has built a solid name worldwide. All the products meet global rules for how well they work and how safe they are for the environment.

Why Is Refrigeration the Fundamental Mechanism in Chiller Systems?

Refrigeration forms the key part of any chiller setup. It handles heat in a smart way. Let’s break down the main ideas that make it work so well.

Thermodynamic Cycle as the Basis of Heat Extraction

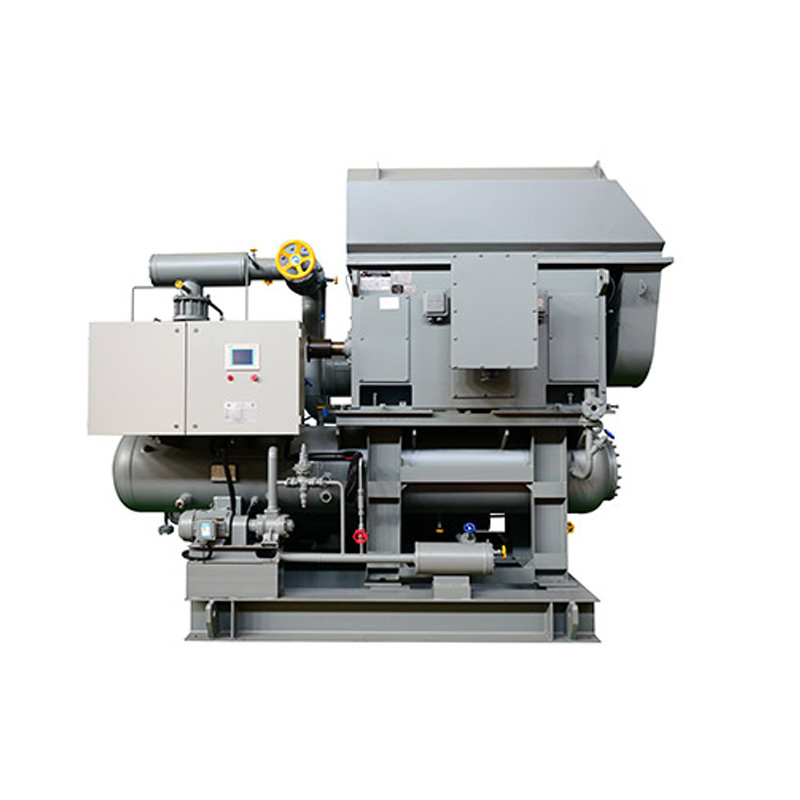

Each chiller runs on a basic cycle that shifts heat around. This cycle can be vapor-compression or absorption. It has four main steps. First comes evaporation. Then compression. After that, condensation. Finally, expansion. To put it plainly, the refrigerant takes in heat when it evaporates. Later, it lets that heat go during condensation. In big factory uses, screw compressors often win out. They last long and handle a wide range of sizes. The LS-Series Screw Chiller uses exact screw compressors. These manage medium to large jobs. They keep chilled water at +5°C to +10°C on the output side. Plus, it has flooded shell-and-tube evaporators. It also includes plate heat exchangers. Both help with quick and effective heat swaps.

Energy Efficiency Through Controlled Temperature Regulation

Stable temperatures matter a lot. They stop damage to stuff or breaks in work flow. Refrigeration shines here. It keeps tight watch on process heat. And it does so without wasting power. For instance, the Red Water Chiller shows this off. It has a strong falling-film evaporator. That one uses a pump to feed liquid. It comes with auto controls that work well. And it swaps heat better than most. These units hold liquid at just 0.25°C. They also reuse cooling water. That makes them great for soaking poultry or seafood in cool baths.

Component Integration for System Optimization

A chiller works best when its parts fit together just right. You have evaporators, condensers, compressors, and expansion valves. They need to team up without issues. That brings top dependability. Custom work changes everything here. MOON-TECH picks the right fluid and setup based on your project’s traits. They match it to what you really need. So, they build the best refrigeration plan for you. Plate exchangers save room. Shell-and-tube ones handle hard jobs. The choice depends on your heat flow. It’s not always straightforward—sometimes site dirt or water type throws a curveball.

How Does Refrigeration Enable Industrial Process Stability?

Refrigeration keeps factory work running smooth. It deals with heat buildup. Now, let’s look at how it handles key challenges in daily operations.

Process Cooling for Thermal Load Management

Fast machines and nonstop runs create extra heat. If you ignore it, things slow down or stop. Even worse, quality drops. Refrigeration pulls away this extra warmth. The Siphon-Type Low-Temperature Brine Chiller fits these tough spots perfectly. It runs on LG series screw compressors. Those are quiet and tough. So, it works well for cold jobs in chemicals or deep food cooling. Places where even small heat changes cause big problems.

Prevention of Thermal Degradation in Manufacturing Lines

Too much heat doesn’t just stall gear. It changes how materials act. That hurts the final product. Steady refrigeration stops this heat damage. It holds everything in the right temp range. Big heat exchange tubes help here. They work even with dirty water. You can clean them fast with hot water. So, less blocking. Fewer fixes needed. Output stays even. This matters in drinks or plastic making.

Continuous Operation with Minimal Downtime

No one likes stopping work at odd hours over a hot compressor. Smart refrigeration uses digital watchers and live checks. They spot trouble early. After finishing the system rebuild, NH₃ stays just in the machine room. They add an active ammonia guard there too. That keeps things safer overall. Remote checks and auto tweaks aren’t extras. They’re must-haves for round-the-clock runs. In multi-shift factories, this setup keeps lights on without surprise halts.

What Are the Engineering Principles Behind Efficient Chiller Design?

Good chiller builds follow clear rules. They focus on smart heat moves and part matches. Here’s a closer look at the basics that drive strong designs.

Heat Exchange Efficiency as a Core Design Parameter

The heat exchanger in your chiller sets the pace. It decides how quick and cheap energy shifts happen. Plate types are small but pack a lot of swap area. Shell-and-tube ones stand up to big tasks. The LS-Series Screw Chiller picks a water-cooled shell-and-tube condenser. It has top-notch tubes for heat work. This cuts power waste. It also holds steady output temps, even when loads change.

Compressor Technology Selection and Performance Matching

Picking the right compressor goes beyond size. It affects your power costs too. Screw types manage big loads without much fuss. Scroll ones suit smaller spots better. The LS-Series Screw Chiller nails this. It covers 1211 to 2489 kW in cooling power. You get choices in evaporator and condenser styles. That fits different needs. It’s practical—lets you scale without starting over.

Control Systems for Adaptive Operation Modes

Going digital is key now for steady work. Smart PLC units track pressure, flow, and heat levels. They tweak compressor speed on the fly. Live sensors help spot small problems early. That stops them from growing big. These setups change with load shifts. They boost how well things run at half speed. No need for hands-on fixes. In real plants, this means fewer surprises and smoother days.

Why Is Refrigerant Selection Critical in System Performance?

Choosing the refrigerant shapes how well your system runs. It ties into heat handling and safety.

Thermophysical Properties Impacting System Efficiency

It’s not only about handling pressure. A refrigerant must grab and drop heat well. Its boiling point sets evaporation push. Latent heat figures into cooling strength. Eco scores affect rules and care needs. For systems with evaporation from -52℃ to 0℃, the NH3/CO2 setup stands as the top pick now and ahead. It’s reliable across wide cold ranges.

Compatibility with System Materials and Components

The best refrigerant won’t harm seals or mix bad with oils. If it does, you get leaks or early breakdowns in bits like seals or valves. On the CO₂ side, the system runs without oil. That boosts heat move efficiency. It fits refrigeration, freezing, chilling, and fresh-keeping tasks. Compared to cascade types, it costs less to set up. This makes it a smart choice for budget-tight projects.

Environmental Compliance and Safety Considerations

Today’s rules demand green choices. Low-GWP fluids are standard in many places. Ones that burn or poison need strict handling under ISO/ASHRAE guides. So, design must cover not just how it works. It also has to fit legal sides. Sometimes, picking one means extra training for the team, which pays off in the long run.

FAQ

Q1: What role does refrigeration play in industrial chillers?

A: Refrigeration facilitates heat removal via thermodynamic cycles—keeping processes stable while conserving energy.

Q2: Which industries benefit most from low-temperature chillers?

A: Industries like chemical processing, seafood handling, and poultry cooling rely heavily on low-temperature systems for consistent thermal management.

Q3: How do control systems improve chiller performance?

A: Digital PLCs adjust compressor speed and monitor key parameters in real-time, helping reduce energy waste and avoid equipment failure.