Sistemas industriais de refrigeração podem economizar energia e funcionar melhor melhorando suas quatro partes principais: compressor, condensador, dispositivo de expansão e evaporador. Para os negócios que pretendem reduzir custos e ser ecológicos, essas mudanças são um movimento inteligente. Com melhorias práticas e exemplos do mundo real, indústrias como processamento de alimentos ou instalações químicas podem reduzir o uso de energia enquanto mantêm sistemas confiáveis. MONTECH, um nome confiável desde 1956, oferece soluções de refrigeração adaptadas para indústrias como logística, alimentos e químicos. Sua equipe de especialistas fornece sistemas sustentáveis de alto desempenho com todo o apoio. Eis como cada componente pode ser adaptado para melhor recuperação de energia, explicado simplesmente com exemplos reais.

Operação de Compressor e Potencial de Melhoria

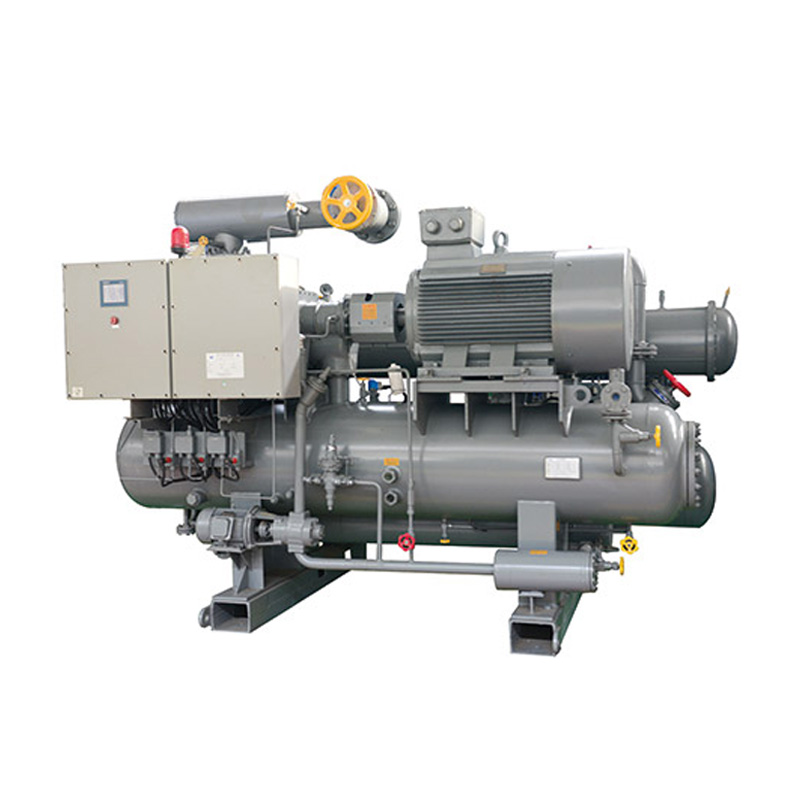

O compressor é o coração do sistema, empurrando o refrigerante para criar refrigeração. Mas ela pode confundir energia se não estiver correcta.

Melhor Eficiência, Menos Poder

Um bom design de compressor economiza eletricidade. O NJ Series Screw Compressor Condensing Unitpor exemplo, usa rotores especiais para reduzir vazamentos e fricção. Isto corta o uso de energia tanto na configuração quente (série Z) como no frio (série D2). Em uma usina de processamento de peixes, essas unidades mantêm os congeladores frios sem aumentar a conta elétrica.

Coincidir o refrigeração com a demanda

Os comprimidores só deveriam trabalhar tão duro quanto necessário. - Dispositivos de frequência variáveis (VFDs) os ralentizam quando a demanda de refrigeração cai, como num armazém tranquilo à noite. Isso evita desperdiçar energia, manter custos baixos.

NJ Series Screw Compressor Features

A série NJ tem um economista seco para ambientes frios. Ele refrigera refrigerante extra antes de se expandir, aumentando a eficiência. Em uma instalação de embalagem de carne, essa instalação congela os produtos mais rápido usando menos energia.

Rôlo do condensador no lançamento de calor

O condensador deixa calor do frigorífico para o ar ou água fora, afetando o quão duro o compressor funciona.

Tratar o calor em diferentes climas

O tempo quente torna os condensadores menos eficientes, aumentando o uso de energia. Um condensador de grande tamanho com controles inteligentes de ventiladores mantém as coisas estables. No Porto Mora de Brunei, condensadores evaporadores manejam calor húmido, refrigerando uma fábrica de gelo de 50 toneladas por dia de forma confiável.

Tamanho e Escolhas de Material

Os condensadores maiores liberam calor melhor, mas precisam de espaço. tubos de cobre com fins de alumínio funcionam bem porque eles transferem calor rápido. Em plantas costeiras, materiais duros lutam contra a raíz, durando mais.

Screw Refrigeration Compressor Unit in Action

Screw Refrigeration Compressor Units muitas vezes usam condensadores evaporadores, que pulverizam água e sopram ar para derramar calor eficientemente. No projeto Guangzhou Port Nansha, com 227.000 toneladas de armazenamento frio, esses condensadores economizam energia enquanto refrigeram espaços enormes.

Performance do Dispositivo de Expansão

O dispositivo de expansão controla o fluxo de refrigerante para o evaporador, reduzindo a pressão para o refrigerante.

Controlar fluxo e pressão

Válvulas de expansão termostatica (TXV) ajustam o fluxo do refrigerante para corresponder às necessidades de refrigeração. Em uma sala de congelação rápida para pizzas congeladas, elas asseguram um refrigeração constante sem desperdiçar energia.

Fomentar o trabalho de evaporação

Uma válvula ruim pode estragar o evaporador, causando refrigeração desigual. Em uma unidade de armazenamento de leite, uma válvula bem calibrada mantém o leite a uma temperatura constante, protegendo a qualidade.

Escolhar a válvula direita

Os válvulos devem corresponder ao tamanho do sistema e ao refrigerante, como CO2 no projeto Shandong Haidu. Lá, 104.000 toneladas de armazenamento de alimentos de mar dependem de válvulas precisas para lidar com CO2 a -25°C, mantendo os congeladores eficientes.

Rôlo do evaporador na absorção de calor

O evaporador retira calor de produtos ou espaços, deixando o refrigerante absorvê-lo enquanto se transforma em gás.

melhor transferência de calor

As plumas e tubos do evaporador decidem o quão rápido ela se refrigera. Em uma fábrica de café seca congelada, designs inteligentes asseguram rápido, até mesmo refrigeração para bloquear o sabor.

Manter o fluxo aéreo mesmo

Bom fluxo de ar evita pontos congelados ou quentes. No armazém congelado de 206.000 toneladas de Wuhan, os refrigeradores de ar no teto espalham o ar frio uniformemente, mantendo comida fresca em espaços enormes.

Grande para tarefas frias

O sistema de cascata NH3/CO2 excele em temperaturas super baixas, de -52°C a 0°C. Na instalação de camarões Promarosa do Ecuador, mantém 650 toneladas de armazenamento gelado, usando menos energia do que sistemas mais antigos. CO2 também funciona bem para a produção de cerveja ou snack, onde o refrigeração exato importa.

Componentes adicionais que apoiam o Ciclo

Outros componentes ajudam o sistema a funcionar suavemente e economizar energia.

Separadores de Petróleo e Lubricação

Os separadores de petróleo impedem que lubrificantes abraçem o evaporador ou condensador. No armazenamento frio da Malásia, mantêm o sistema de amônia eficiente, protegendo equipamentos e economizando energia.

Economizadores para Extra Enfriamento

Os economistas secas acrescentam energia de refrigeração sem mais eletricidade. Em uma fábrica química de refrigeração a -30°C, o economizador da série NJ economiza energia enquanto mantém as coisas estables.

VFD para ajustes inteligentes

Os VFD ajustam as velocidades motoras para corresponder às necessidades. No armazenamento frio ASRS da Tailândia, eles cortam o uso de energia através da lentidão dos ventiladores durante tempos de baixa demanda, perfeito para centros logísticos ocupados.

Estratégias de optimização para recuperação de energia

Os sistemas de refrigeração podem pegar calor desperdiçado e usá-lo, cortando perdas de energia.

Reutilizando o calor de Condensadores

O calor do condensador pode aquecer água para limpeza ou escritórios de calor. No projeto de Wuhan, o calor do sistema NH3/CO2 aquece espaços próximos, economizando combustível.

Sistemas de Recuperação de Calor

Os ciclos podem capturar calor de compressores para líquidos pré-aquecidos. Em uma usina química, isso reduz a necessidade de aquecedores adicionais, reduzindo os custos.

Monitorização inteligente

O digital controla as temperaturas da pista e ajusta as configurações em tempo real. No Porto de Guangzhou, eles otimizam 24 compressores, economizando energia ajustando ventiladores em noites mais frias.

Avantagens Técnicos da MOON-TECH

As unidades da MOON-TECH s ão construídas para trabalhos difíceis como logística ou refrigeração química.

Compressores eficientes da série NJ

Essas unidades usam projetos compactos e tubos de alta eficiência, fornecendo forte refrigeração com menos energia. Em Shandong Haidu, eles refrigeram 104.000 toneladas de armazenamento de alimentos de mar eficientemente.

Design Modular for Easy Fixes

As configurações modulares deixam os trabalhadores consertar uma parte sem parar tudo. Na fábrica de gelo do Brunei, isso mantém a produção em funcionamento durante reparações.

habilidades de refrigeração comprovadas

MOON-TECH's soluçãocomo o armazenamento de camarões da Promarosa, mostra sua habilidade com sistemas NH3/CO2, tornando-os uma escolha máxima para necessidades complex a s de refrigeração.

FAQ

Q1: Como um compressor de screw melhora a eficiência de refrigeração?

A: Reduz perdas de vazamento interno ao mesmo tempo que mantém proporções de compressão consistentes em cargas variadas através de perfis de rotor avançados.

Q2: Que papel um economista desempenha em uma unidade de condensação de parafusos?

A: Recupera vapor de pressão intermediária para aumentar a capacidade de refrigeração sem entrada de energia adicional, melhorando significativamente a eficiência global do ciclo.

Q3: Por que escolher CO ₂- sistemas baseados em aplicações de baixa temperatura?

A: CO₂ é especialmente adequado para sistemas de refrigeração de baixa temperatura como o congelador individual devido à sua alta capacidade de refrigeração volumétrica em temperaturas de evaporação muito baixas (-50°C).

Q4: Pode o resíduo de calor de condensadores ser reutilizado eficazmente?

A: Sim; o calor recuperado pode ser redirecionado para água pré-aquecida ou outros fluidos usados em outros lugares dentro dos processos da sua instalação – aumentando o ROI total do sistema.