In today’s factory setting, power use often stands as the biggest changeable expense hitting your profits. Improving heat handling has become more than a mere engineering choice; it serves as a key money-saving step. MONTECH, founded in 1956, focuses on low-temperature cooling, eco-friendly heating, and power-chemical gear. Through custom tailored industrial solutions combined with fresh research efforts, they supply secure and power-efficient setups to clients across over 120 nations. Whether you need exact heat regulation for tricky chemical tasks or huge setup projects, their broad comprehensive service network makes sure your plant runs at top performance over its full operating span.

Economic Impact of High Efficiency Industrial Heat Exchange

An industrial heat exchanger goes beyond basic equipment; it acts as a vital driver for expense control in your operation. When you switch to better exchange methods, you recover heat that might otherwise go unused, which leads straight to major yearly cost cuts.

Direct reduction of operational electricity costs

Better exchange setups lower the load on compressors and cut fan operating hours. Since your heat flow works smoothly, the setup hits needed heat levels quicker, thereby trimming your regular power charges.

Significant decrease in industrial water consumption

Improved closed-circuit and vapor-based methods cut down on steady water additions. In areas short on water or with high costs, this drop in supply needs stops thousands of dollars from simply vanishing into thin air.

Extension of core machinery service life

By keeping a steady heat setup, you shield your main gear from heat wear. Accurate chilling avoids excess warmth in oils and joint seals, which lessens costly sudden fixes and component swaps.

Advanced Evaporative Technology for Optimal Thermal Control

When your plant deals with heavy heat demands, vapor cooling gives a stronger power-saving option over old ways. By using the hidden heat in evaporation, such systems shift more power with reduced mechanical work.

MOON-TECH Evaporative Condenser with latent heat principle

O Condensador de Evaporação employs a clever mist and air flow layout to release heat. This method yields cooler condensing points than air-only setups, which greatly raises the full Energy Efficiency Ratio (EER) of your cooling operation.

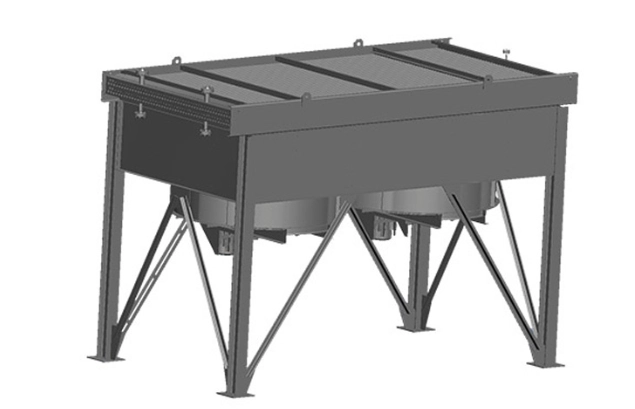

Composite cooling mechanism of Industrial Composite Air Cooler

In spots with changing weather heat, the Cooler Aéreo Composito Industrial offers a flexible fix. It shifts easily between dry and damp operations, so you avoid using extra water or power beyond what the surroundings truly demand.

Smart water-saving features in humid environments

Current control units detect outside moisture levels and tweak mist timings as needed. Thus, they stop extra water loss in wet periods, yet deliver full chilling power amid intense summer warmth.

Robust Air Cooling Solutions for Resource Scarcity Areas

In places where water handling proves tough or rules on the environment tighten, air-chilled options deliver a steady and easy-care route to heat balance.

Dry cooling advantage of Air-Cooled Heat Exchangers

O Trocador de calor frio pelo ar skips the need for a water chill loop completely. As a result, it avoids buildup, dirt, and germ growth, which mainly cause drops in output for water-reliant systems.

High-efficiency finned tubes for maximum heat dissipation

Through smart finned pipe shapes, these devices expand the area for heat shift. You achieve strong chilling even in a compact area, which lets you make better use of your plant space.

Customized Air Cooler designs for cold storage logistics

For big logistics sites, a custom Friador de ar guarantees even heat spread. This proves crucial in mechanized tall storage areas, where a small heat shift might harm goods and cause large money hits.

Compact Heat Exchange Systems for Specialized Industrial Needs

Some factory tasks, like air splitting or gas freezing, demand sharp heat shifts in very limited room. Tight exchange tech holds the answer for handling these intense heat loads.

Aluminium Plate-Fin Heat Exchanger for cryogenic applications

O Trocador de calor de placa-fina de alumínio sets the benchmark for dense heat flow. Its welded build lets it manage various flows at once, proving essential for involved power and chemical work.

Multi-stream integration capability in limited factory spaces

Since these pieces handle multiple liquids in one unit, you can drop several standalone exchangers. This streamlines your pipes and setup, cutting startup costs and ongoing care spots.

Superior thermal conductivity of aerospace-grade aluminium materials

Aluminum offers fine heat flow and stays flexible at deep chill points. Therefore, your setup stays safe and effective, even at lows like -161°C for methane freezing.

Energy Recovery Strategies Through Smart System Integration

The top tier of power saving comes not from one part, but from overall system teamwork. Grabbing unused heat and feeding it back into your work flow can turn your plant into an efficient cycle.

Waste heat capturing for secondary industrial processes

Heat exchangers grab warmth from compressor output or waste gases. You can then apply this no-cost power to warm boiler input water or supply hot water for site washing, sharply lowering your fuel needs.

MOON-TECH systematic solutions for carbon footprint reduction

With full power oversight, plants can hit big drops in CO2 output. This readies your firm for tougher green laws and boosts your image as a green producer.

Real-time monitoring for preventive energy loss maintenance

Built-in smart detectors in the exchange setup let you track output live. By spotting early fouling or pressure falls, you handle aimed fixes before power waste turns into a heavy cost load.

Why MOON-TECH Is Your Premier Partner in Heat Exchange Technology

Linking with a supplier who grasps the whole of factory design matters for lasting wins. A solid heat exchanger works best with proper system linking and backing.

Decades of engineering excellence in global EPC projects

Work on vast build jobs, like concrete chilling for big dams and nuclear sites, shows skill in detail and size. This design background assures even tough factory needs get met with tested steadiness.

Full-lifecycle service from professional consultation to maintenance

The tie starts with expert advice and plan setup, so you pick the fitting tech for your weather and tasks. Over the gear’s run, skilled training and upgrades keep your site sharp and current.

Proven track record with international industrial success cases

With close to a thousand auto storage builds and thousands of power-chemical installs around the world, these setups’ dependability shows up on every land. From oil sites in Central Asia to food plants in Southeast Asia, such fixes reliably bring power savings.

FAQ

Q1: How do I know if my current heat exchanger is wasting energy?

A: Common signs include an unexplained rise in energy bills, the need to run pumps at higher speeds to maintain temperatures, or visible scale buildup on the exchange surfaces. A professional thermal audit can quantify the exact energy loss and calculate your potential ROI for an upgrade.

Q2: What makes an evaporative condenser more efficient than a cooling tower and heat exchanger combo?

A: An evaporative condenser combines both functions into one unit. By cooling the refrigerant directly through evaporation on the tube surface, it eliminates the “approach temperature” loss found in heat exchanger/cooling tower loops, leading to lower head pressures and less compressor power consumption.

Q3: Can air-cooled systems work effectively in high-temperature tropical climates?

A: Yes. While air-cooled systems are more challenging in hot climates, using high-efficiency finned tubes and variable frequency drives allows them to maintain process temperatures. In some cases, a composite cooler is used to provide extra cooling boost during the hottest hours of the day.

Q4: Why is aluminum used for plate-fin exchangers instead of stainless steel?

A: Aluminum has a much higher thermal conductivity than stainless steel, meaning it transfers heat more efficiently. It also becomes stronger at cryogenic temperatures, making it the safest and most efficient choice for deep-cooling applications.