À medida que as regras ambientais ficam mais estritas e os preços da energia subem, as empresas procuram novos métodos de refrigeração. Esses métodos devem lidar com tarefas diárias e encaixar com alvos verdes mundiais. O sistema de refrigeração de CO2 leva o caminho para uso na fábrica. Mostra forte eficiência, pequeno dano ao planeta, e se encaixa bem em diferentes níveis frios.

Um melhor jogador nessa mudança é MONTECHcomeçou em 1956. Tem uma história de novas ideias em instalações de refrigeração e aquecimento na fábrica. MOON-TECH foca nos refrigerantes naturais e tecnologia de poupança de energia. Elas dão planos completos prontos para uso para fábrica, loja e necessidades da cidade. Seu alcance cobre mais de 120 países. Eles oferecem ajuda completa, desde a instalação de projetos até a fabricação de equipamentos, a união de sistemas e cuidados após venda.

Por que o sistema de refrigeração de CO2 atrai atenção no refrigeramento industrial?

As empresas mudam para um trabalho mais limpo enquanto adotam refrigerantes naturais como CO2 (R744). Este movimento acelera rapidamente.

Pressão crescente para cumprir as regras ambientais?

Regras mundiais expulsam refrigerantes falsos com alto potencial de aquecimento global (GWP). Então, fábricas se viram para outras escolhas para seguir regras duradouras. CO₂ movimenta o calor bem. Assim, o tamanho das ferramentas diminui, o uso de energia diminui e a eficiência aumenta. Isto estabelece configurações de CO2 como uma troca verde que corresponde aos pactos climáticos globais. Além disso, seu potencial de depleção zero de ozono (ODP) aumenta sua confiança verde.

A crescente demanda de soluções de refrigeração eficientes em termos de energia?

A eficiência do trabalho é importante para reduzir os custos de energia e o preço de propriedade total. As instalações de CO2 usam ciclos transcríticos e subcríticos para impulsionar o trabalho de calor. Eles também permitem reutilização de calor, então o calor perdido se transforma em água ou calor ambiente. Bons traços de calor e fluxo elevam muito a COP global. Isso os traz em fábricas de consciência de energia.

Desafios com sistemas de refrigeração tradicionais?

Os refrigerantes falsos trazem perigos como veneno, risco de incêndio e altos custos de correção dos vazamentos. Essas configurações não concordam com novas regras verdes sem grandes melhorias que custam muito. Mas o refrigeração de CO2 dá uma base sólida para o futuro. Isso resolve esses problemas imediatamente.

Sostenibilidade Ambiental como Prioridade Estratégica

Modos verdes não são uma escolha agora. Eles são uma necessidade para negócios, empurrados pelas regras e o comprador quer.

Baixo potencial de aquecimento global de refrigerante de CO2

O CO2 tem um GWP de apenas 1. O topo é o refrigerante mais seguro do tempo lá fora. Usá-lo ajuda objetivos de corte de carbono a longo prazo sem perder qualidade de trabalho. CO₂ o resfriamento direto corre a baixa pressão. O CO ₂ parte funciona sem petróleo, então o calor se move com economia de alta energia. Isto é adequado às plantas que querem um estado de carbono zero.

Refrigerante Natural com potencial de esgotamento de ozono zero

CO2 vem da natureza. Não é veneno, não propenso ao incêndio, e seguro se tratado corretamente. Ele corta os riscos ecológicos dos halocarbonos. Isso diminui sua planta o eco marca muito.

Alinhamento Regulatório através dos mercados globais

As instalações de CO2 seguem as principais regras mundiais como o Regulamento F-Gas e a Emenda Kigali. Sua ampla adaptação as faz ótimas para fábricas de exportação que buscam entrada no mercado mundial.

Eficiência Operacional em Aplicações Industriais

O trabalho na fábrica precisa de saída constante em mudar cargas e configurações. A configuração de CO2 brilha aqui todas as vezes.

Alto desempenho termodinâmico sob condições diferentes

CO₂ sistemas de refrigerantes secundários funcionam frequentemente entre -50 e 0%. Eles têm um limite especial em segurança e saída. Esse espaço ajuda muitos passos da fábrica, do congelamento profundo ao frio ligeiro. Ela mantém resultados constantes independentemente da zona fria.

poupanças de energia através da integração da recuperação de calor

- Captura o calor residual da descarga do compressor

- Reutiliza energia para aquecimento de espaço ou água

- Corta a dependência de aquecimento auxiliar baseado em combustíveis fósseis

Essa união aumenta a eficiência total da configuração por uma boa margem.

Reduzido tempo para baixo através de melhoramentos da confiabilidade do sistema

As instalações de refrigeração de CO2 têm menos peças em movimento e construções duras. Eles gerem pontos de alta pressão sem tremer no trabalho. O CO ₂ o lado fica sem petróleo. A transfer ência de calor economiza energia bem. Ambos adicionam a vida mais longa e menos tempo de reparação.

Avanços tecnológicos que apoiam a adoção

Um novo trabalho constante é vital para aumentar o uso e desenho do refrigeração de CO2.

Inovação na Tecnologia de Mudança de Fase por MOON-TECH

O Unidade de refrigeração de mudança de fase de alta eficiência de CO2 traz um novo passo na economia de calor através da tecnologia de mudança de fase. Ela inclui:

- Design modular compacto para instalação fácil

- Alta COP com consumo mínimo de potência de bomba

- frigoríficos ecológicos R290 e R744

Esta unidade troca bem os velhos refrigeradores. Acaba com problemas de raíz e corta o uso de energia.

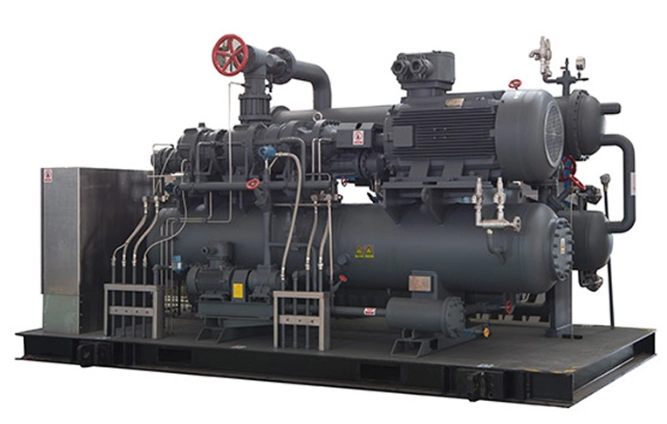

Desenvolvimento de compressores de CO2 de alta eficiência por MOON-TECH

O Compressor de CO2 dá exato controle em ciclos subcríticos e transcríticos:

- Engineering for continuous high-pressure operation

- Compressão de um só ou dois estágios

- Design de prova de explosão com opções de lubrificação de grado alimentício

Isso mantém o trabalho constante em áreas fábricas que precisam de níveis de confiança estritos.

Avanços na Integração e Automatização do Sistema

Os controles inteligentes mudam a saída para encaixar nos estados de carga. Eles também permitem assistir longe para reparações antecipadas. Essas surpresas param. Eles ajudam a sintonizar o uso de energia agora.

Considerações Económicas Driving Market Shift

O senso monetário muitas vezes consegue a escala de novas escolhas tecnológicas.

Custo competitivo do ciclo de vida comparado aos sistemas sintéticos

Os custos iniciais podem ficar mais elevados, mas os custos de execução mais baixos os equilibram em breve. Vs. o sistema cascado, custos para investir diminuição, principalmente para configurações indiretas de CO2. Eles reutilizam antigas instalações com pouco trabalho de mudança.

Incentivos governamentais para apoiar tecnologias verdes

Ajuda planos como despesas fiscais, montagens de crédito de carbono e fundos tecnológicos crescem para refrigerantes verdes. Esses curtos tempos de retorno. É melhor calcular ROI para instalações grandes.

Escalabilidade através de cenários de refrigeração industrial

Os edifícios modulares deixam o crescimento fácil de pequenos lugares para grandes zonas fábricas. Seus auxílios de estilo de conexão fácil se juntam a configurações agora sem grandes reformas. Ele apoia o crescimento passo a passo com pouco chateado.

Por que MOON-TECH é o parceiro preferido para soluções de refrigeração de CO2

Escolhar o melhor colega de equipe se seu gasto traz ganho duradouro ou problemas rápidos.

Expertiza Provada em Tecnologias de Refrigeração Natural

Com mais de 60 anos de refrigeração de novas ideias, MOON-TECH oferece a melhor habilidade em construindo planos de refrigeração verdeSuas habilidades vão da palestra de design para ajuda mundial.

Portfólio de produtos de liderança industrial tailoreado para eficiência

Os elementos chave da MOON-TECH como a Unidade de Refrigeração de Mudança de Fase de Alta Eficiência e o Compressor de CO2 mostram novos trabalhos para o melhor resultado. Eles dão melhor poupança com menos dano ecológico.

Capacidades de serviço de fim a fim assegurar sucesso a longo prazo

Seus serviços de vida inteira, desde conselhos tecnológicos até treinamento de trabalhadores, tornam a configuração suave e a produção estável. Vejam mais sobre sua ampla ajuda através Página de Serviço.

FAQ

Q1: O que é um sistema de refrigeração de CO2?

A: É um sistema de refrigeração que usa dióxido de carbono (R744) como um refrigerante natural conhecido por sua baixa GWP e alta eficiência termodinâmica.

Q2: Por que escolher CO2 em vez de refrigerantes sintéticos tradicionais?

A: CO2 tem zero potencial de depleção de ozono, um GWP de apenas 1, melhores propriedades de transfer ência de calor, e alinha-se com regulamentos globais sobre redução de gás-F.

Q3: Os sistemas de refrigeração de CO2 podem ser integrados em configurações existentes?

A: Sim. O equipamento original do sistema de amônia é utilizado na maior medida possível, especialmente com sistemas indiretos que requerem retrofitting mínimo.

Q4: Existem incentivos financeiros para adotar a refrigeração de CO2?

A: Sim. Muitas regiões oferecem subvenções, créditos de carbono e incentivos fiscais para implementar tecnologias de refrigerantes ecológicas.