South Africa’s poultry industry deals with tough pressures from soaring energy bills, unreliable electricity, tougher export rules, and the constant push to keep meat quality high in hot weather. Up-to-date freezing methods tackle these problems head-on. They freeze products quicker and more evenly, which helps keep the natural feel of the meat, cuts down on moisture loss, and allows steady high-output runs. You end up with lower running costs, easier meeting of worldwide cleanliness rules, and a stronger edge in the market thanks to better quick-freezing setups.

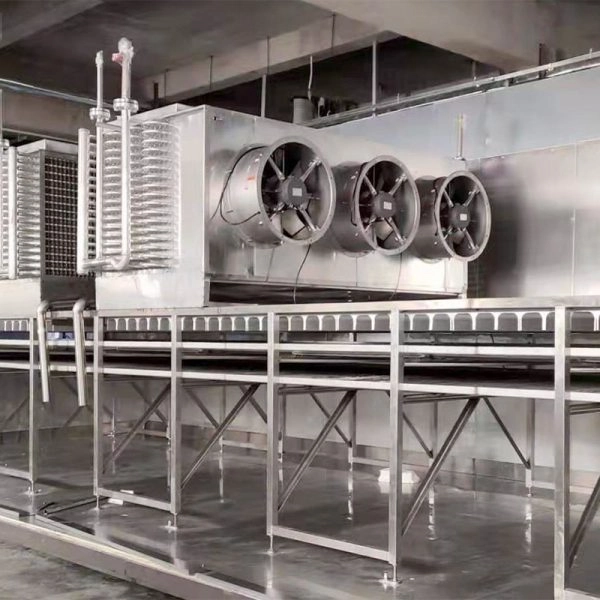

As an expert in industrial refrigeration, МУНА-ТЕХ is a solid name since 1956 that really knows low-temperature freezing and quick-freezing gear for food work, especially poultry lines. They shine at putting together smart, power-saving full setups. A recent example shows their spiral freezer running smoothly in a South African poultry facility, proving steady work and strong food safety levels.

Challenges Facing South Africa Poultry Processing Today

Poultry plants across South Africa handle several ongoing hurdles that hurt profits and final product standards. Unsteady power cuts interrupt daily work, while warm outside conditions speed up spoilage unless freezing happens fast and evenly. Tough overseas rules call for very little moisture escape and steady clean practices, but older techniques frequently lack the needed speed and cost control.

Energy Costs and Power Instability Issues

Load-shedding happens often, so facilities must turn to backup generators that drive up electricity spending. Newer setups featuring smart compressors and well-planned air movement keep power needs low and deliver dependable results even when the grid fails.

Product Quality and Dehydration Losses

When freezing takes too long, big ice crystals form and harm cell walls, causing extra drip and lower usable amounts. Quick modern freezing locks in moisture and keeps the right bite, so you deliver top-grade chicken items suited for local shops and foreign buyers.

Meeting Strict Export and Hygiene Standards

Buyers abroad insist on low germ levels and clear process tracking. Built-in automatic wash features together with closed designs help hold sanitary levels steady and match global food safety guidelines without much extra hassle.

Benefits of Advanced IQF Freezing Technology

Individual Quick Freezing, or IQF, changes the game for poultry handling by freezing items rapidly and keeping them separate. This method stops pieces from sticking together, holds their original shape nicely, and traps freshness much better than old batch-style freezing ever could.

Superior Heat Transfer Efficiency

Strong vertical forced air currents combined with top-performing evaporators bring about swift and uniform cooling. As a result, you get shorter freeze cycles and steady temperatures right through the core, which works perfectly for cut-up chicken portions.

Reduced Product Weight Loss

Careful quick freezing slashes moisture loss during the process, often saving several percentage points of weight that would otherwise vanish with slower techniques. That extra retained weight turns straight into better output and higher earnings on valuable poultry runs.

Continuous High-Volume Production

Smooth conveyor setups let production flow without breaks, easily handling large daily amounts. Because of this steady flow, you can grow output while keeping labor and energy spending under tight control.

Key Types of Quick Freezers for Poultry Applications

Picking the proper freezer comes down to your product shape and daily volume targets. Choices cover spiral, tunnel, and plate styles, and each brings clear strengths suited to different poultry jobs.

Spiral Quick Freezers stand out when you need to freeze loose poultry bits such as thighs or nuggets. The self-stacking belt plus vertical air pattern gives outstanding efficiency, supporting outputs between 500 and 3000 kg per hour.

Spiral Quick Freezers for Individual Poultry Pieces

These machines manage separate or portioned pieces with hardly any clumping. Built-in automatic clean-in-place washing makes upkeep simple and keeps hygiene levels high at all times.

Intelligent Tunnel Quick Freezers for Tray-Packed Products

Intelligent Tunnel Quick Freezers fit tray-loaded poultry very well thanks to automatic feed systems and live data tracking. They take up less floor area, cut down on worker effort, and still push through high volumes reliably.

Plate Quick Freezers for Block Poultry Freezing

Plate Quick Freezers offer direct-contact freezing for solid blocks or pressed items. Contact on both sides brings quick, even results while using relatively little energy for each batch.

Implementation Considerations for South African Plants

Putting new freezing gear in place calls for adjustments that fit local realities such as shaky electricity and hot surroundings. Pay close attention to smooth joining, power savings, and simple upkeep so the investment pays off for years.

Site-Specific Customization Options

Tailor freezer sizes and layouts to match your building setup and output aims. Combined packages link quick freezers tightly with dependable cooling sources, creating the best overall performance possible.

Energy-Efficient Refrigeration Integration

Connect quick freezers to modern compressors and evaporative condensers to bring electricity use way down. Such arrangements handle South Africa’s power troubles well and keep total running expenses noticeably lower.

Automated Cleaning and Maintenance Systems

Factory-fitted clean-in-place routines plus monitoring tools cut stoppages and hand work. Routine checks keep everything running smoothly and help the equipment last longer under tough daily conditions.

Measuring ROI from Modern Freezing Upgrades

Putting money into better freezing brings obvious money-back gains through smarter running and nicer product quality. Keep an eye on numbers like power draw, finished yield, and daily throughput to see the real payoff clearly.

Lower Operational Energy Consumption

Smart designs along with adjustable controls drop electricity needs quite a bit. Those savings build up steadily, particularly when local energy prices stay high.

Higher Throughput and Yield Improvements

Quicker freezing lifts daily production amounts while saving more of the original product weight. You gain extra profit without needing to enlarge the plant itself.

Enhanced Product Shelf Life and Market Value

Top-notch freezing holds texture and looks longer after packing. Higher quality opens doors to better prices and firmer standing in export markets.

Why Choose MOON-TECH as Your Freezing Solutions Partner

MOON-TECH brings more than 70 years of solid know-how, successful worldwide turnkey experience, and a proven history in food freezing work. Their strength lies in putting together complete systems that join screw refrigeration compressors with quick freezers to give steady, power-smart results. A working spiral freezer setup in a South African poultry site shows dependable running, excellent safety practices, and full support for nonstop output. You gain from made-to-fit answers, worldwide approvals, broad service coverage, and constant technical help. Reach out to MOON-TECH soon to talk about upgrades shaped for your exact situation.

Часто задаваемые вопросы

Q1: What makes modern freezing essential for South African poultry plants?

A: Modern freezing tackles power cuts, hot weather, moisture loss, and tough export demands. It delivers quicker, cleaner freezing that raises usable yield and trims overall costs effectively.

Q2: Which quick freezer type suits portioned chicken pieces best?

A: Spiral quick freezers handle individual items like thighs very well. They provide nonstop work, very little moisture escape, and excellent heat movement through strong vertical airflow.

Q3: How do these solutions handle power outages common in South Africa?

A: Efficient compressors and careful designs keep power needs low. Sturdy builds maintain steady work even when backup generators take over during grid failures.

Q4: Can modern freezers improve product yield and reduce waste?

A: Yes, fast IQF cuts weight loss from drying and keeps natural texture intact. This leads to more sellable product and far less waste than older freezing ways.

Q5: What support can you expect after installation?

A: You receive complete lifecycle help that covers upkeep, fault checks, improvements, and staff training. All of this keeps the system performing well and reliably for many years.