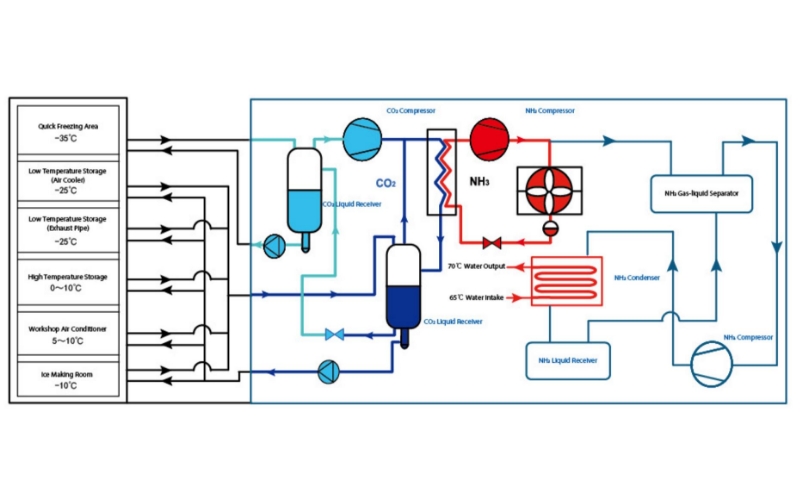

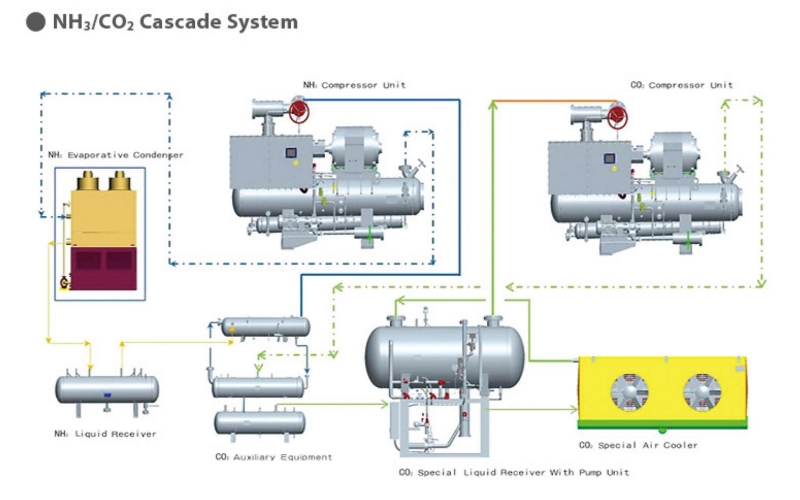

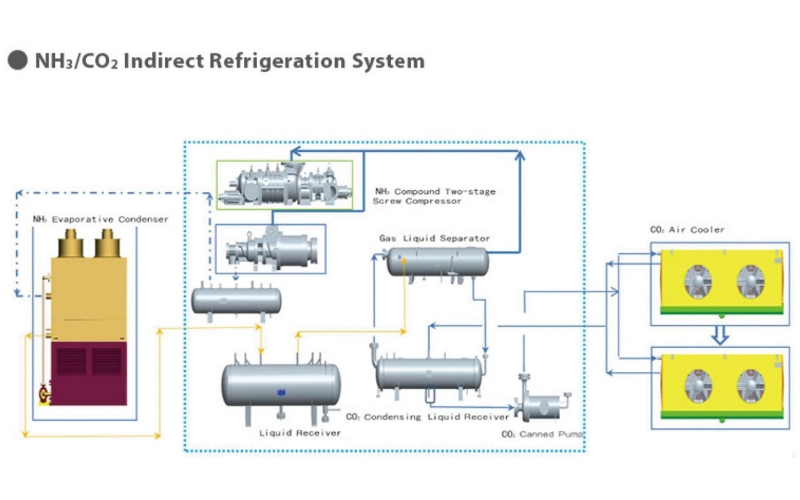

At present, CO2 refrigeration system technology is widely used in meat slaughtering, aquatic processing, beer and beverage, prepared food, fruit and vegetable processing, dairy products and cold drinks, industrial ice making, cold chain logistics, winter sports venues, chemical process cooling and other fields.

Among the refrigeration systems with the evaporation temperature ranging from -52℃ to 0℃ , the NH3/CO2 system is the best refrigeration solution from now on or in the long run.