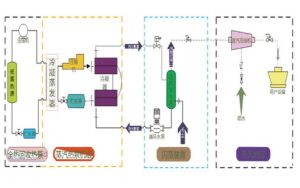

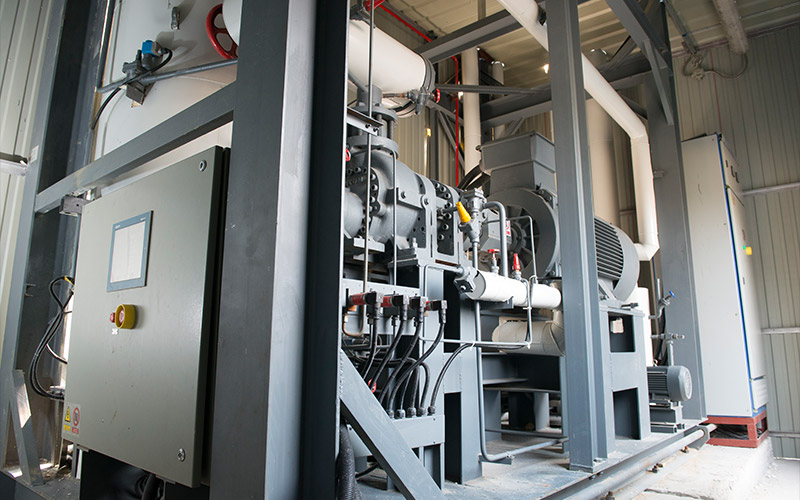

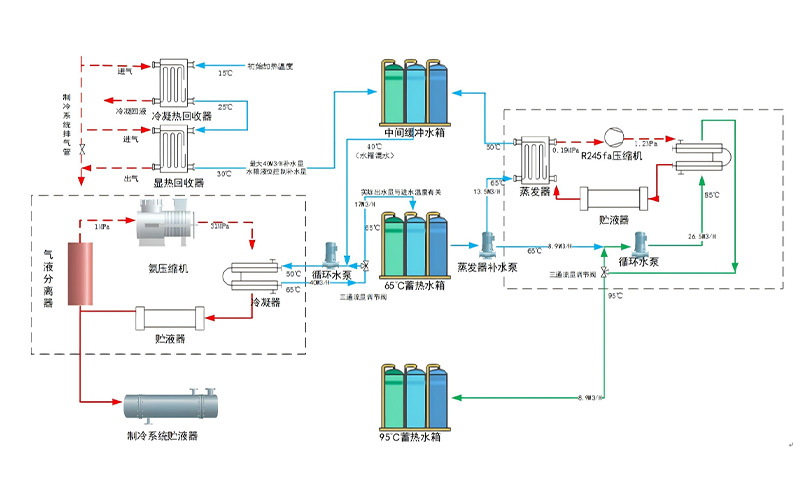

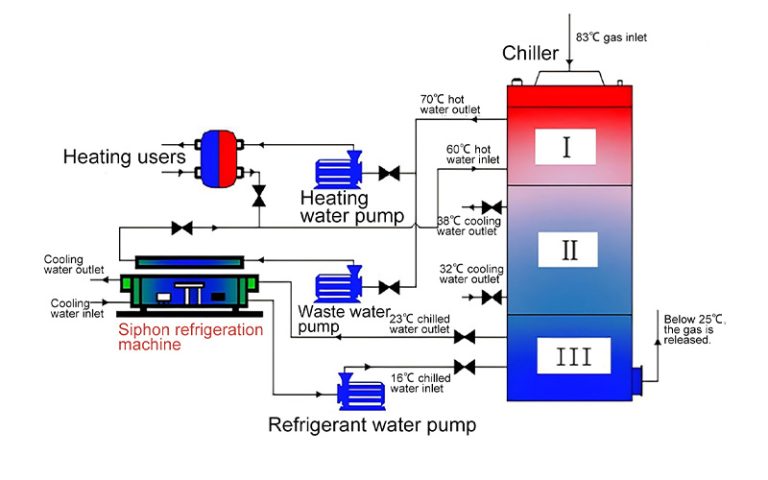

The technology of Moon-Tech’s condenser waste heat recovery system offers multiple heating methods, including sensible heat recovery, high-temperature heat pumps, off-peak electricity thermal storage, steam heat pumps, and steam boosters. Each solution provides different heating functions and is applied in scenarios that require high energy efficiency and simultaneous heating and cooling, such as livestock slaughtering, seafood processing (aquaculture), dairy production, frozen foods, beer brewing, food and pharmaceutical drying, large hotels, sports venues, swimming pool hot bath services, and residential heating, among others.