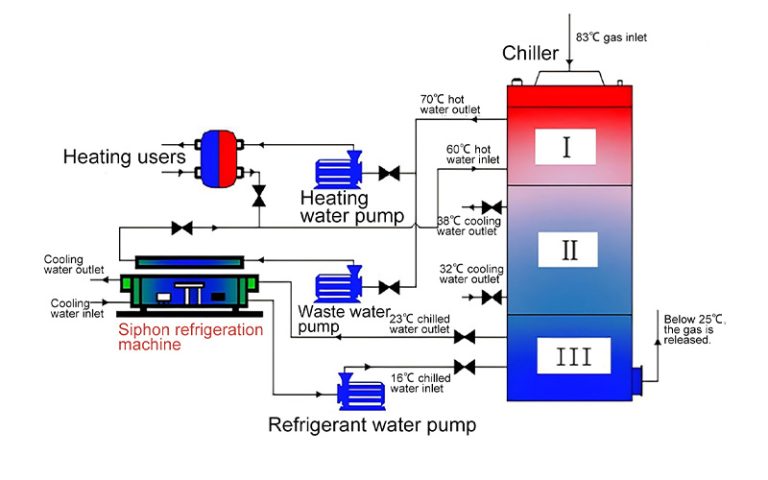

In major hydropower and nuclear power infrastructures, dam bodies and ring island structures typically use large-volume roller-compacted concrete (RCC) pouring, with massive volumes often reaching millions of cubic meters per hour. The hydration heat released is intense. To prevent structural cracks and joint misalignment caused by thermal expansion and contraction—which can affect dam strength and service life—it is essential to control the concrete placement temperature, maintaining stable fluctuations between 7°C and 15°C.

MOON-TECH is among the earliest domestic companies to develop and implement dynamic ice slurry systems on an engineering scale. We hold approximately 60% of the market share in China’s hydropower and nuclear power concrete temperature control system sector. Our capabilities include independent integration of ice slurry systems, chilled water systems, aggregate cooling, and automatic control product lines.

In recent years, dynamic ice slurry systems—with their excellent instantaneous cooling capacity, homogeneity, and controllability—have gradually replaced traditional crushed ice cooling methods, becoming the new mainstream technology for large-volume concrete temperature control systems.