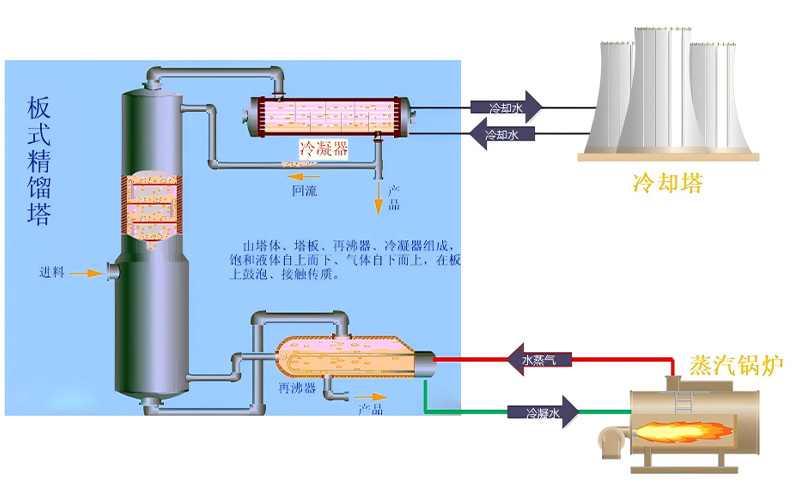

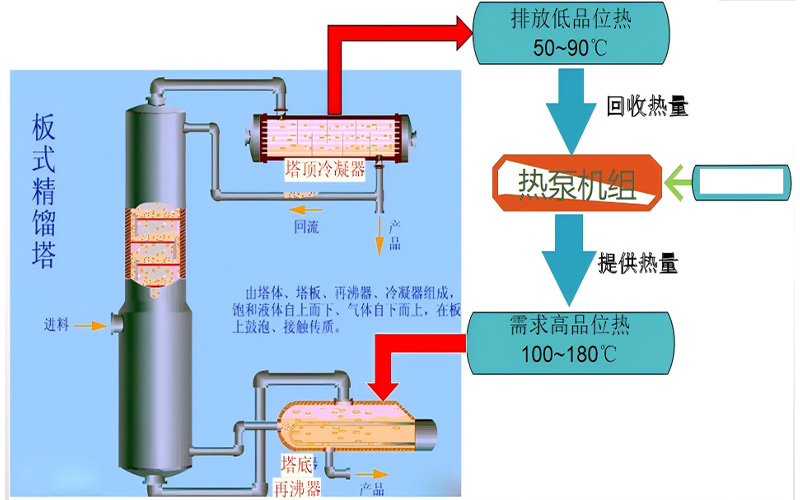

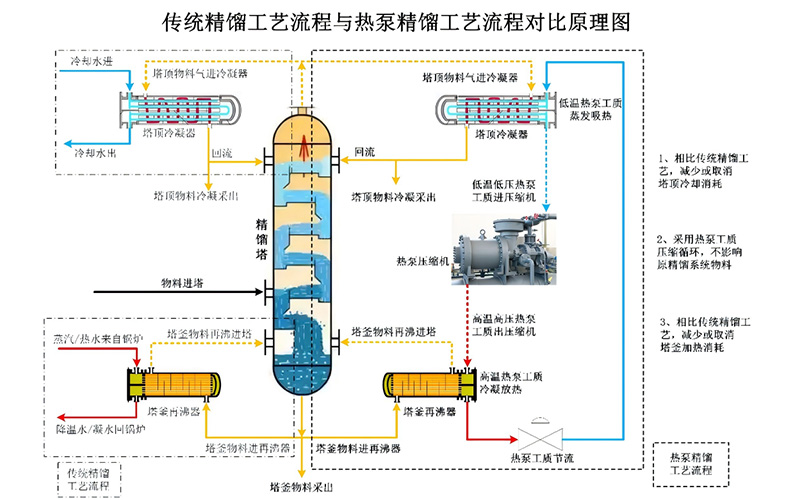

MOON-TECH fully leverages its technical and product advantages by utilizing a series of stable, mature, reliable, and advanced technologies and products to recover low-grade residual heat and waste heat from industrial production processes. This recovered energy is then upgraded to higher-grade energy for use in process production or urban district heating. On one hand, this approach reduces energy consumption per unit of product; on the other hand, it delivers significant economic and social benefits. It is widely applied in energy-intensive industries such as steel, chemical, building materials, electric power, petrochemical, non-ferrous metals, textiles, and light industry.