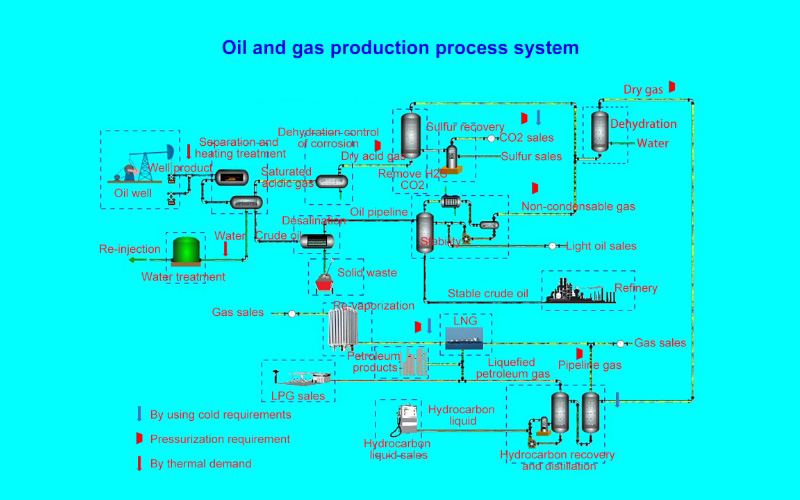

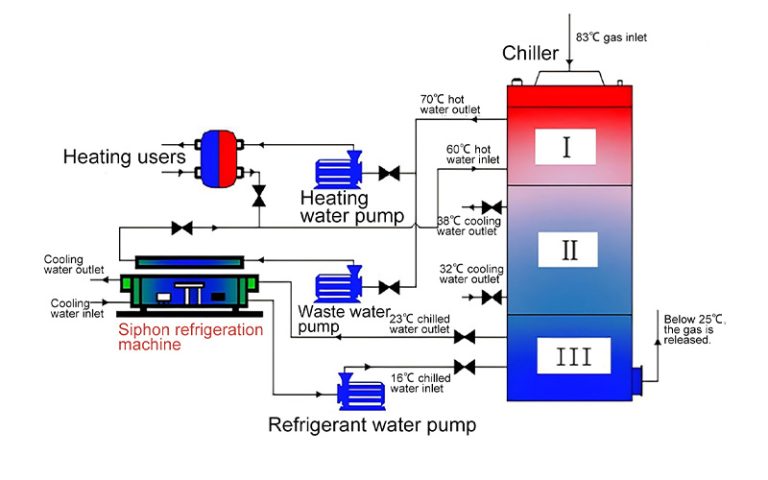

Since 2006, MOON-TECH has been deeply engaged in the niche market of associated gas compression and liquefaction in oil and gas fields, gradually establishing a mature technical system and a complete product portfolio. The company is committed to providing reliable and efficient gas treatment solutions for oil and gas fields worldwide. Our systems are widely applied in natural gas boosting, negative pressure gas recovery in oil production plants, gas pressure regulation, petrochemical tail gas compression, and cryogenic liquefaction.