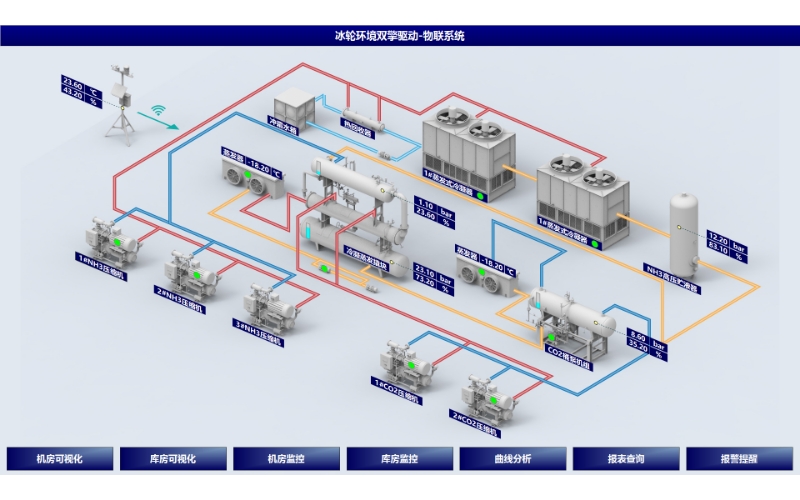

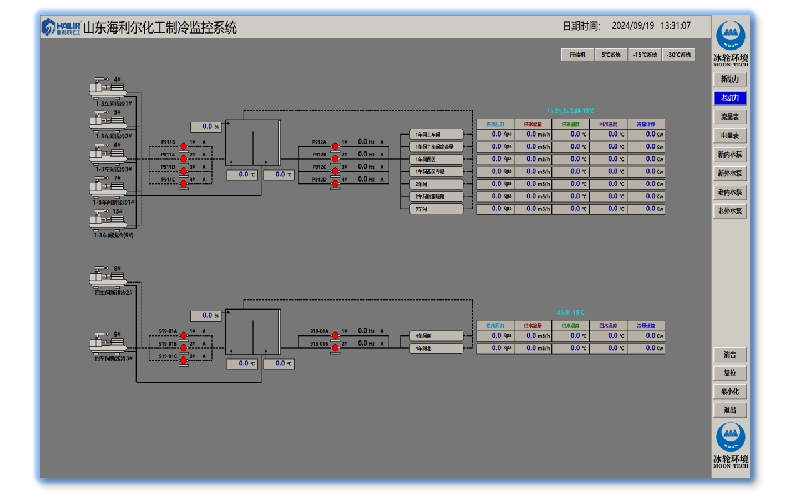

Traditional operation and maintenance (O&M) face three major pain points: passive responses leading to delays, data silos causing isolated information, and inefficient energy consumption resulting in high costs. To address these challenges, the smart O&M solution offers innovative solutions:

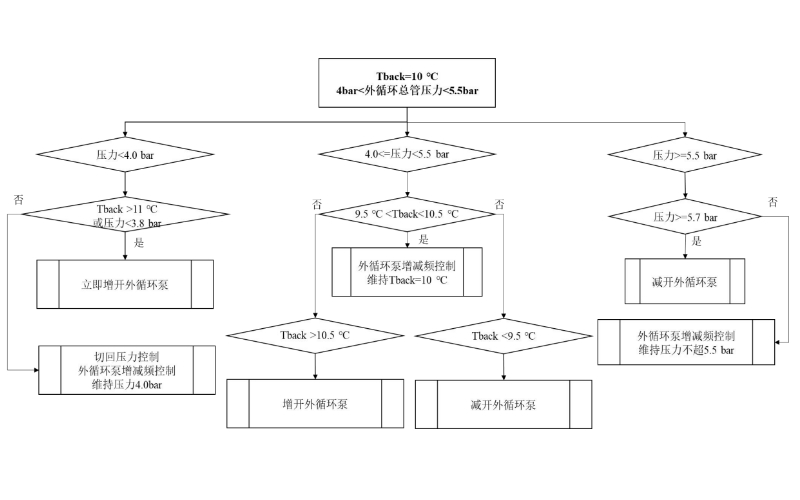

AI Predictive Maintenance: Provides a 12-hour early warning of potential failures, avoiding delayed responses.

Cloud-Edge Collaborative Data Platform: Ensures 100% interconnectivity of devices, breaking down data silos.

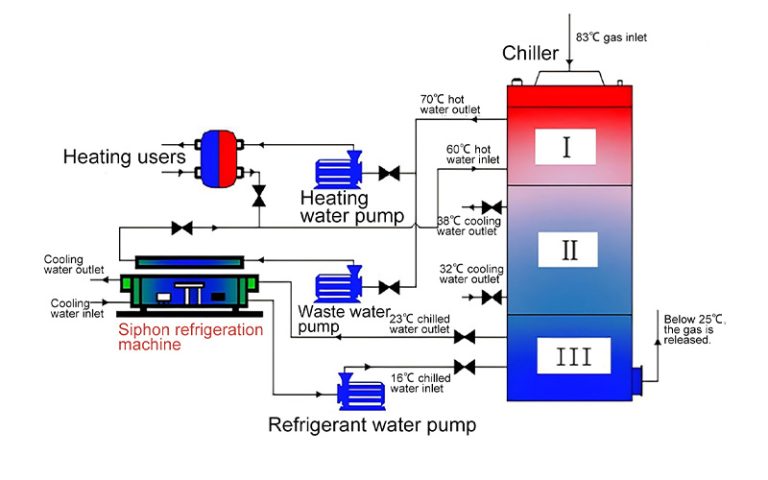

Dynamic Algorithm Optimization: Helps enterprises achieve ≥20% energy savings, significantly reducing operational costs.

This approach makes your equipment management more efficient, secure, and intelligent!

Core Concept: “Automation ≠ Intelligence. Smart O&M is a paradigm revolution driven by data and model integration.”