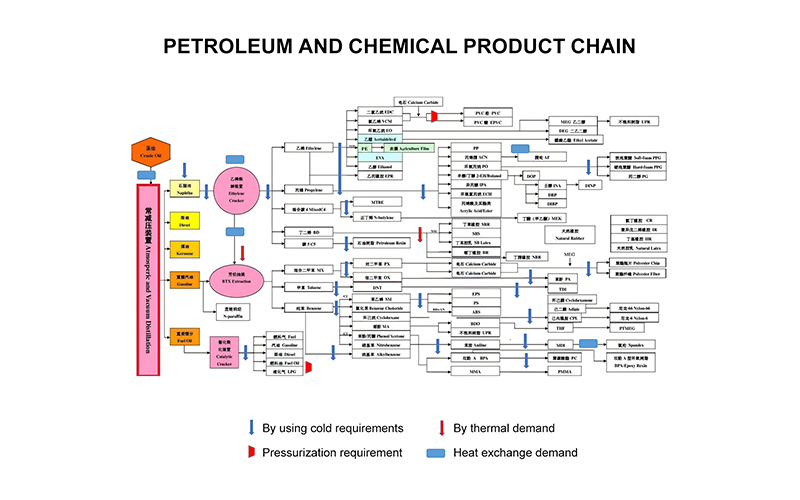

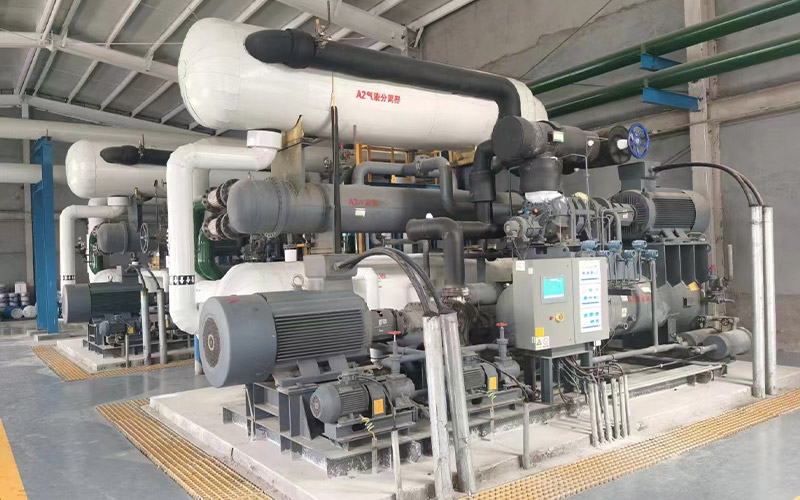

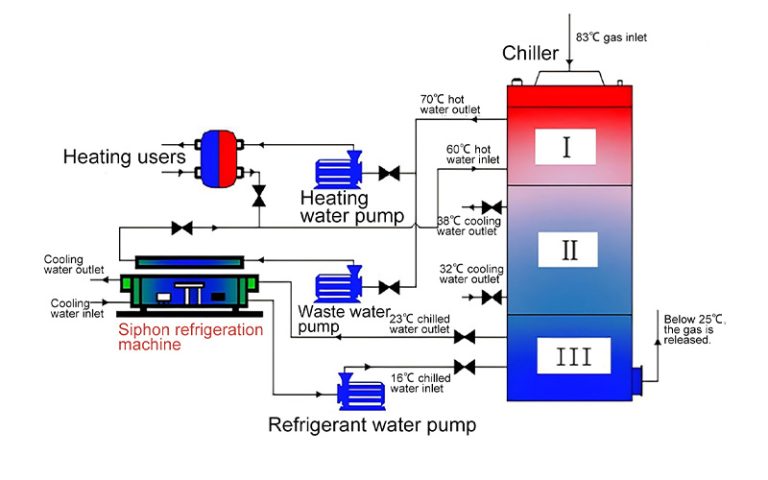

With China’s refining industry shifting from traditional standalone refining to an integrated “refining + petrochemical” model, a large number of downstream chemical products have emerged. Large-scale refining facilities now place higher demands on the stability, reliability, and low-temperature performance of refrigeration systems. Since 2016, MOON-TECH has been deeply involved in various domestic and international integrated refining projects, offering full-process refrigeration and heat recovery solutions—including chilled water systems, low-temperature brine systems, liquid cooling, and gas condensation. With a market share of approximately 50%, MOON-TECH holds a leading position in this niche sector.