Refrigeration science sits at the heart of many big industries today. It keeps food fresh, chemicals steady, and tech gear cool. This field does much more than just chill things down. It guards product quality, keeps workers safe, follows tough rules, and helps the planet stay green.

Few names match MOON-TECH when you hunt for top-notch refrigeration gear. The company started back in 1956. It builds full cooling and heating setups for customers all over the world. Their lineup covers strong compressor units, chillers, and easy-to-grow modular kits made for huge factory jobs. Smart designs mix with auto controls. This combo helps cut power bills, fix things less often, and hit green targets without sweat.

What Is Refrigeration Science and Why Does It Matter for Modern Industries?

Refrigeration means moving heat from one spot to another. The goal stays simple: drop the temp where you need it cold. In factories, this job follows basic rules of heat flow, liquid-to-gas shifts, and fluid motion. Three main steps run the show. First, evaporators suck in heat. Next, compressors squeeze the refrigerant to bump up pressure and warmth. Last, condensers push that heat out in a controlled way. These steps create steady cold zones. Fresh food stays good. Chemical mixes do not blow up.

Fundamental Principles of Industrial Refrigeration

Phase change rules the game here. Picture a refrigerant turning from liquid to gas at low pressure. It grabs heat from nearby air or water as it boils. Then, under high pressure, it flips back to liquid and dumps that heat outside. Simple heat laws guide every swap of energy. Temp, pressure, and heat content must stay in check. If any slip, the whole setup wastes power or fails flat.

Role of Refrigeration in Industrial Processes

Many factories live or die by exact temps. Think of a meat plant. One degree too warm, and bacteria grow fast. Or a drug lab. Wrong chill, and the batch turns useless. In oil refineries, tiny shifts spark fires. Refrigeration stops those nightmares cold.

Impact on Energy Efficiency and Sustainability

Power costs climb high these days. Green rules push harder. Smart refrigeration fights back. It trims wasted juice with tight compressor runs, slick heat swaps, and brainy controls. MOON-TECH picks the right fluid and layout for each job. They match real needs on site. Factories hit output goals and cut smoke at the same time.

How Has Refrigeration Technology Evolved to Meet Industrial Demands?

Cooling tech started crude. Ice blocks, ammonia leaks, clunky machines. Now it shines sharp and clean.

From Basic Cooling to Precision Engineering

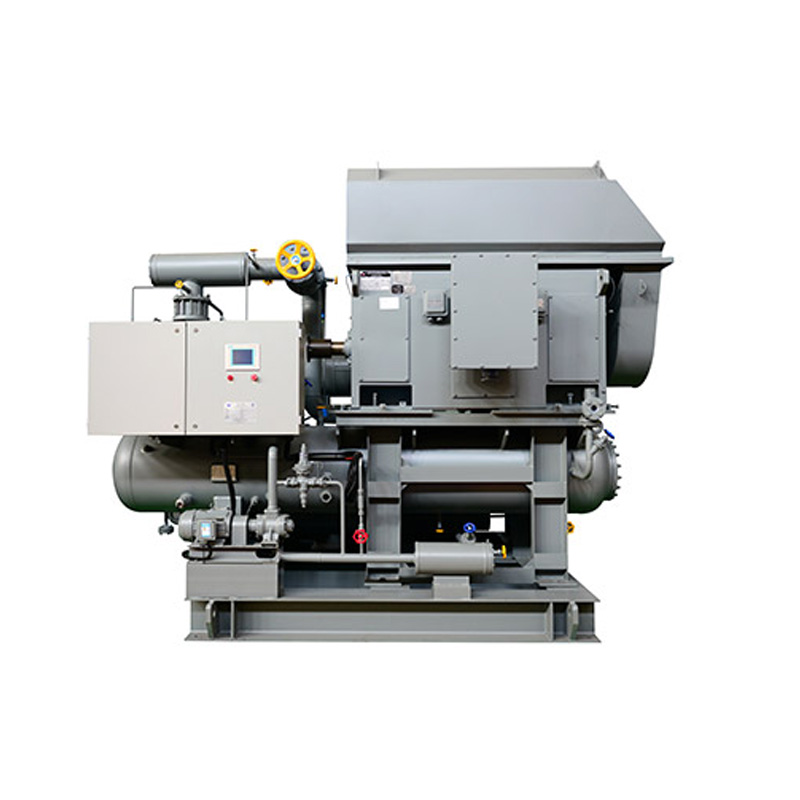

Old vapor cycles gave way to screw setups. These handle wild load swings without hiccups. Take the Semi-Hermetic Screw Refrigeration Compressor Unit. It pumps out 74.8 kW to 1652 kW of chill. Works for high, mid, or low temps. The half-sealed build cuts moving parts. Fewer leaks. Parallel compressors let you dial capacity up or down smooth.

Integration of Automation and Smart Controls

Auto brains watch every second. Sensors spot load changes. Compressors speed up or slow down on the fly. Cloud links send alerts to phones. Fix small glitches before they grow big. One warehouse tech told me his team shaved two hours off weekly checks thanks to live graphs.

Modular and Scalable System Design

Factories grow in steps, not leaps. The LS-Series Screw Chiller fits that pace. Add modules as lines expand. No need to rip out old gear. Keeps cold steady while the plant doubles output.

Which Industries Are Being Transformed by Advanced Refrigeration Science?

New cooling tricks shake up whole fields. Rules get stricter. Demands rise. Tech answers.

Food Processing and Cold Chain Logistics

CO₂ shines in deep freeze jobs. Think solo freezers, blast rooms, big cold stores for ready meals. It keeps meat from farm to fork fresh. Slaughter lines, fish plants, breweries, milk tanks, juice lines all lean on CO₂ loops. One chicken packer cut shrink by 15 percent with tighter chill zones.

Chemical and Petrochemical Sectors

CO₂ cascade kits nail minus 50 Celsius without sweat. Safer than old ammonia in open rooms. Labs report fewer bad batches. Refineries avoid costly flares.

Data Centers, Electronics, and High-Tech Manufacturing

Servers cook themselves fast. Precision units hold 18 to 27 Celsius rock solid. Chip test benches need the same. Poultry plants, seafood docks, textile dye vats borrow the same chill tech. Steady cold means steady profits.

What Makes MOON-TECH’s Refrigeration Solutions Stand Out?

Tough jobs need tough gear. MOON-TECH builds to last.

Engineering Excellence in Screw Compressor Units

The Semi-Hermetic Screw Refrigeration Compressor Unit takes heavy abuse. Runs non-stop in dusty plants. Half-seal stops gas slips. Service techs swap parts in half a day.

Customizable LS-Series Screw Chillers for Diverse Needs

LS-Series Screw Chiller bends to fit. Pick R507 or CO₂. Grow from one module to ten. Green rules change by country. These units pass every test.

Global Service Network with Turnkey Solutions

MOON-TECH hands you the keys. Design, build, start, fix. Teams fly in from hubs worldwide. One oil rig off Africa got a full CO₂ plant in six weeks flat.

How Do MOON-TECH Products Improve Operational Efficiency?

Savings show in bills, uptime, and easy fits.

Energy-Saving Performance Metrics in Real Applications

Tight cycles plus slick swaps drop kilowatt use. A juice factory logged 18 percent less juice on the meter after install. Cold stayed the same. Smiles grew wider.

Low Maintenance Requirements with Long-Term Reliability

Strong shells fight rust. Fewer spin parts mean longer peace. One dairy ran three years between oil changes.

Enhanced System Integration Capabilities

New pipes hook to old without wall breaks. SCADA screens show every valve. Upgrade one floor, keep the rest humming.

Why Is Sustainability a Key Driver in Refrigeration Innovation?

Green is not a fad. It is the new rule book.

Eco-Friendly Refrigerants and Compliance Standards

CO₂ beats old gases hands down. No oil on the cold side. Heat moves fast. Fits freeze, chill, or fresh hold. Cheaper than cascade twins.

Heat Recovery and Waste Reduction Technologies

Hot gas leaves condensers. Grab it. Heat water to 60 or 85 Celsius. Or push steam to 200. Free warmth for showers or boilers.

Lifecycle Assessment in Product Development

Build to recycle. Pick steels that melt clean. Track wear with apps. Swap bad parts early. End game plans keep junk low.

FAQ

Q1: What is the ideal refrigerant for low-temperature industrial applications?

A: CO₂ fits low temp jobs like solo freezers, blast rooms, and cold stores. It runs low pressure and moves heat fast.

Q2: How do smart controls improve refrigeration performance?

A: They watch live data. Twist compressor speed to match need. Save juice.

Q3: Can existing ammonia-based systems be upgraded sustainably?

A: Keep old ammonia gear. Run NH₃ only in the machine room. Safer for the floor.

Q4: What distinguishes semi-hermetic screw compressors in industrial use?

A: Half-seal cuts wear parts. Life stretches. Fixes drop.