Turnkey Solutions

At MOON-TECH, we provide comprehensive, fully customized refrigeration and heating solutions designed to meet the specialized needs of diverse industries.

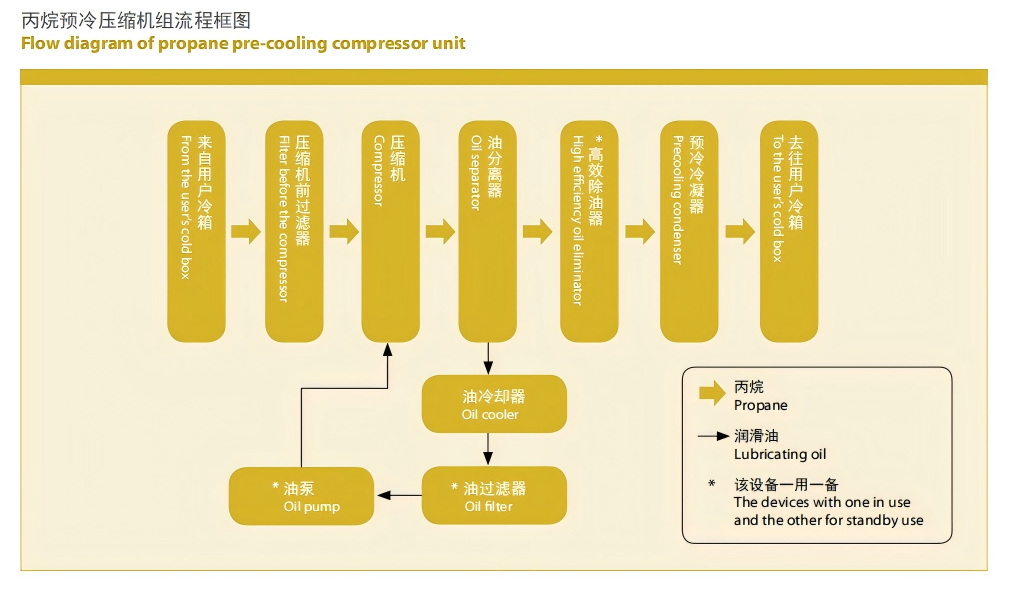

This refrigeration cycle uses propane (R290) as the working fluid. Low-temperature, low-pressure refrigerant gas from the user’s cold box is drawn into the compressor, compressed, and converted into high-temperature, high-pressure gas. It then enters the oil separator, where most of the lubricating oil is separated. The gas then flows into the condenser, where it exchanges heat with air/water. The heat released is then carried away by the air/water, condensing the propane into a liquid. This liquid is then sent to the cold box to provide pre-cooling for the natural gas and mixed refrigerant.

In the compressor oil circuit, oil from the compressor unit’s oil separator enters the oil cooler, where it exchanges heat with the air/water, where the heat is carried away. The cooled oil passes through the oil filter and then enters the oil pump, where it is pressurized and returned to the compressor, providing lubrication and cooling. The oil supply temperature is controlled by an oil temperature control valve.

Basic Process:

This refrigeration cycle uses propane (R290) as the working fluid. Low-temperature, low-pressure refrigerant gas from the user’s cold box is drawn into the compressor, compressed, and converted into high-temperature, high-pressure gas. It then enters the oil separator, where most of the lubricating oil is separated. The gas then flows into the condenser, where it exchanges heat with air/water. The heat released is then carried away by the air/water. The propane is condensed into a liquid and then sent to the cold box to provide pre-cooling for the natural gas and mixed refrigerant.

In the compressor oil circuit, oil from the compressor unit’s oil separator enters the oil cooler, where it exchanges heat with the air/water. The heat is then carried away by the air/water. The cooled oil passes through the oil filter and enters the oil pump, where it is pressurized and returned to the compressor, providing lubrication and cooling. The oil supply temperature is controlled by an oil temperature control valve.

Applicable conditions of the unit

| Project | |

| Inlet pressure MPa(G) | 0~0.5 |

| Outlet pressure MPa(G) | 0.5~2.0 |

| Inlet temperature ℃ | >-50 |

| Outlet temperature ℃ | <90 |

| Flow regulation range % | 10~100 |

| Flow regulation mode of compressor | Slide valve* |

*:Compressor flow rate:Combined variable frequency+slide valve for regulation

Table of technical parameters

BOG compressor/exhaust pressure 1.6MPa(G)

| Item | Unit | NJLG450 | NUJLG550 | NJLG650 | NJLG850 | NJLG1050 | NJLG1250 | NUJLG1450 | NJLG1650 | |||

| COMPRESS

|

Compressor model | LG25(V) BS | LG25(V) BM | LG25(V) BL | LG32(V) BS | LG32(V) BM | LG32(V)BL | LG40(V) | LG40(V) BM | |||

| Cooling capacity | kW | 439.2 | 550.7 | 681.8 | 855.9 | 1048.4 | 1220.5 | 1492.2 | 1694 | |||

| Compressor inlet pressure | MPa(G) |

0.02~0.04 |

||||||||||

| Compressor outlet pressure | MPa(G) | 1.4~1.6 | ||||||||||

| Transmitting power of shaft | kW | 298 | 366.4 | 453.3 | 574.3 | 701.9 | 819.5 | 1072 | 1242.7 | |||

| Rotation speed | rpm | 2960 | 2960 | 2960 | 2960 | 2960 | 2960 | 2960 | 2960 | |||

|

Main motor |

Power supply | 10KV/3PH/50Hz | ||||||||||

| Explosion-proof grade of

motor |

EX dIIBT4 | |||||||||||

| Rated power of motor | kW | 355 | 400 | 500 | 630 | 800 | 900 | 1250 | 1400 | |||

| Starting mode | Direct starting | |||||||||||

| Motor speed | r/min | 2960 | ||||||||||

|

Condenser |

Type | Air-cooled/water-cooled | ||||||||||

| Gas inlet temperature | ℃ | 80 | ||||||||||

| Gas condensing

temperature |

℃ |

50/40 |

||||||||||

| Inlet air/water

temperature |

℃ |

40/32 |

||||||||||

| Explosion-proof grade of fan motor |

EX dIIBT4 |

|||||||||||

| Condensing load | kW | 737 | 917 | 1135 | 1430 | 1750 | 2040 | 2564 | 2937 | |||

| Item | Unit | NULG450 | NJLG550 | NJLG650 | NJLG850 | NJLG1050 | NUJLG1250 | NJLG1450 | NJLG1650 | ||

| Lubricating oil system | Oil pump flow rate | L/min | 220 | 220 | 220 | 400 | 400 | 400 | 800 | 800 | |

| Number of oil pump(s) | Piece | 2 (one in use and the other for standby use) | |||||||||

|

Oil pump/Motor |

Power | kW/piece | 4 | 4 | 4 | 7.5 | 7.5 | 7.5 | 11 | 11 | |

| Electrical system | 380KV/3PH/50Hz | ||||||||||

| Explosion-proof

grade |

EX dIIBT4 |

||||||||||

| Starting mode | Direct starting | ||||||||||

| Rotation speed | r/min | 1450 | |||||||||

*The evaporating temperature is-35’C and the condensing temperature +40’C at the cooling capacity (the evaporating temperature can be adjustedaccording to the user’s process).

At MOON-TECH, we provide comprehensive, fully customized refrigeration and heating solutions designed to meet the specialized needs of diverse industries.