Turnkey Solutions

At MOON-TECH, we provide comprehensive, fully customized refrigeration and heating solutions designed to meet the specialized needs of diverse industries.

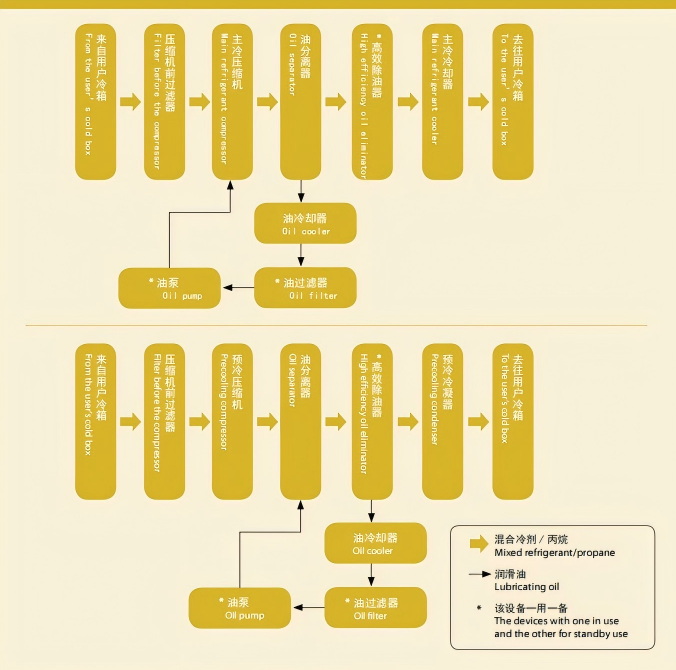

Main cooling cycle: Low-pressure mixed refrigerant exits the user’s cold box and is drawn into the main cooling compressor. After compression, it becomes a high-temperature, high-pressure gas. It then enters an oil separator to remove most of the lubricating oil, then enters a high-efficiency degreaser to remove any remaining lubricating oil. It then enters the main cooling system’s aftercooler for heat exchange with air/water. The heat released is carried away by the air/water, and the mixed refrigerant finally enters the cold box.

Precooling cycle: Using propane (R290) as the refrigerant, low-temperature, low-pressure refrigerant exits the user’s cold box and is drawn into the precooling compressor. After compression, it becomes a high-temperature, high-pressure gas. It then enters an oil separator to remove most of the lubricating oil, then enters a high-efficiency degreaser to remove any remaining lubricating oil. It then enters a condenser for heat exchange with air/water, where the heat released is carried away by the air/water. After condensing into a liquid, the refrigerant enters the cold box.

The screw compressor adopts a semi-enclosed structure design with no shaft seal and zero leakage; the unit is assembled in the factory and transported as a whole on a skid, which reduces the amount of on-site construction and shortens the construction period.

Ice wheel mixed refrigerant screw compressor unit is mainly used in small natural gas liquefaction to LNG, light hydrocarbon recovery, BOG gas, helium recovery and other industries.

Table of technical parameters (Dual stage compression)

| Rated daily liquefaction capacity | 10⁴Nm³/d | 0.5 | 1 | 2 | 5 | 10 | |

|

Stage l compressor |

|||||||

|

Compressor

|

Compressor model | BF12B | BF16BM | BF20BM | BF25BS | BF32BS | |

| Compressor inlet pressure | MPa(G) |

0.3 – 0.5 |

|||||

| Compressor outlet pressure | MPa(G) |

1.2 – 1.4 |

|||||

| Transmitting power of shaft | kW | 61 | 126 | 244 | 393 | 758 | |

| Rotation speed | rpm | 2960 | 2960 | 2960 | 2960 | 2960 | |

|

Main motor

|

Power supply |

380V/3PH/50Hz |

10kV/3PH/50Hz |

||||

| Explosion – proof grade of motor |

EX dIIBT4 |

||||||

| Rated power of motor | kW | 75 | 160 | 280 | 450 | 900 | |

| Starting mode |

Star – delta starting |

Direct starting |

|||||

| Motor speed) | r/min | 2960 | 2960 | 2960 | 2960 | 2960 | |

|

After – cooler

|

Type |

Air – cooled/water – cooled |

|||||

| Outlet temperature | ℃ |

50 |

|||||

| Inlet air temperature | ℃ |

40 |

|||||

|

Stage II compressor |

|||||||

| Compressor

|

Compressor model | BF12R | BF16R | BF20R | BF25R | BF32R | |

| Compressor inlet pressure | MPa(G) |

1.2 – 1.4 |

|||||

| Compressor outlet pressure | MPa(G) |

3.5 – 4.0 |

|||||

| Transmitting power of shaft | kW | 80 | 160 | 322 | 519 | 1002 | |

| Rotation speed | rpm | 2960 | 2960 | 2960 | 2960 | 2960 | |

|

Main motor

|

Power supply |

380V/3PH/50Hz |

10kV/3PH/50Hz | ||||

| Explosion – proof grade of motor |

EX dIIBT4 |

||||||

| Rated power of motor | kW | 90 | 180 | 355 | 560 | 1120 | |

| Starting mode |

Star – delta starting |

Direct starting |

|||||

| Motor speed | r/min | 1460 |

2960 |

||||

| After – cooler

|

Type |

Air – cooled/water – cooled |

|||||

| Outlet temperature | ℃ |

50 |

|||||

| Inlet air temperature | ℃ |

40 |

|||||

At MOON-TECH, we provide comprehensive, fully customized refrigeration and heating solutions designed to meet the specialized needs of diverse industries.